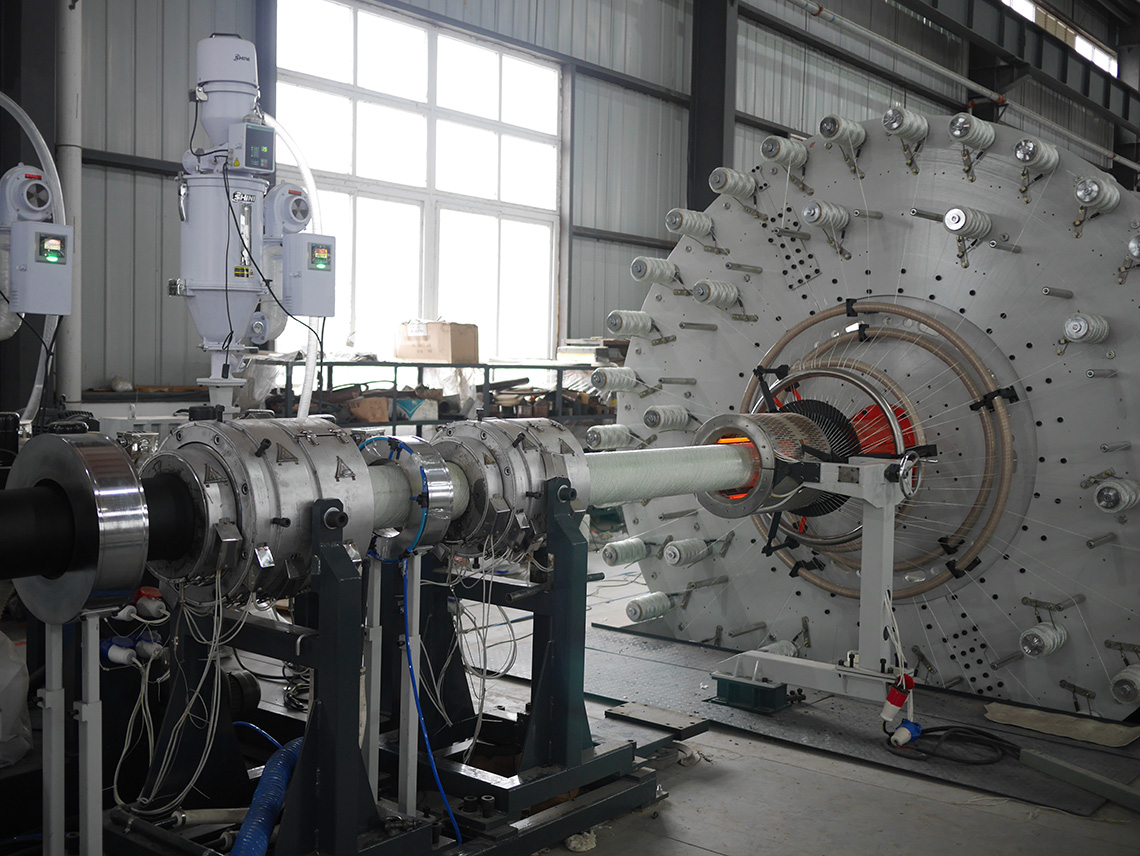

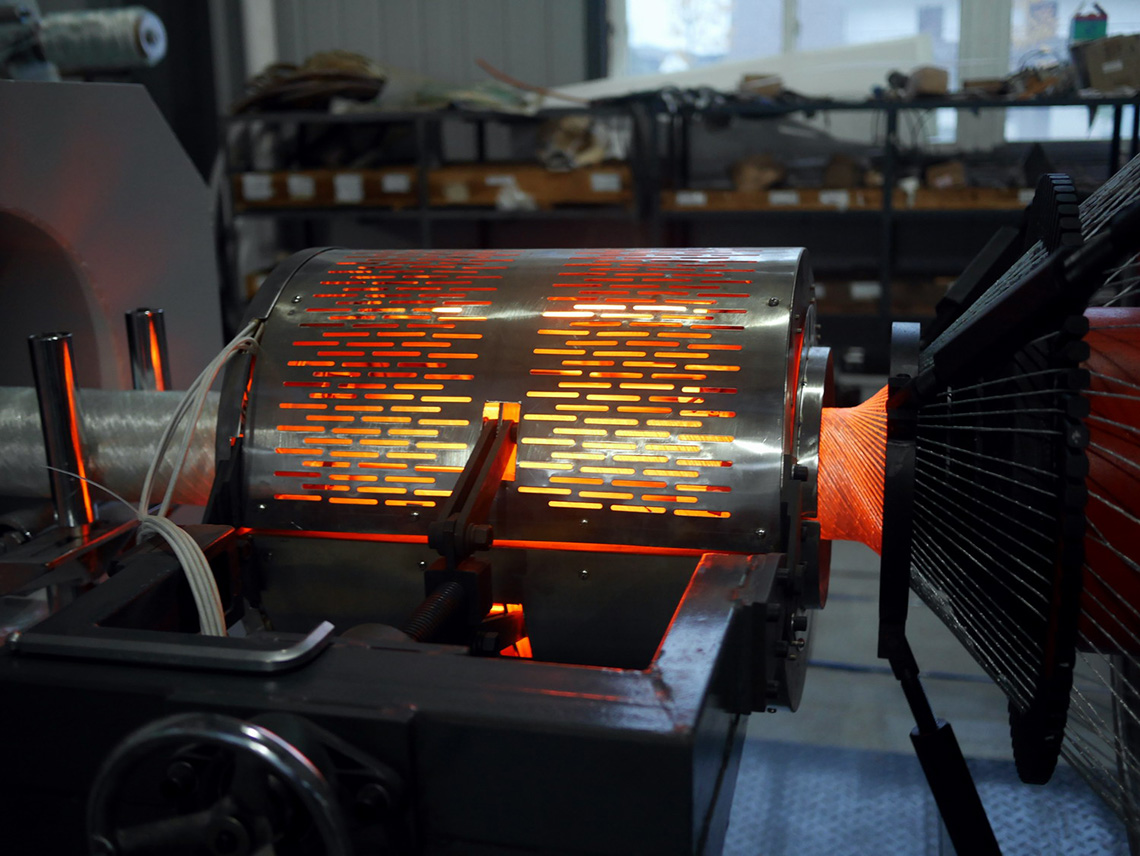

Fiberglass Pipe (RTP) Production Line

Glass Fiber Roving Reinforced Thermoplastic Pipe (RTP)

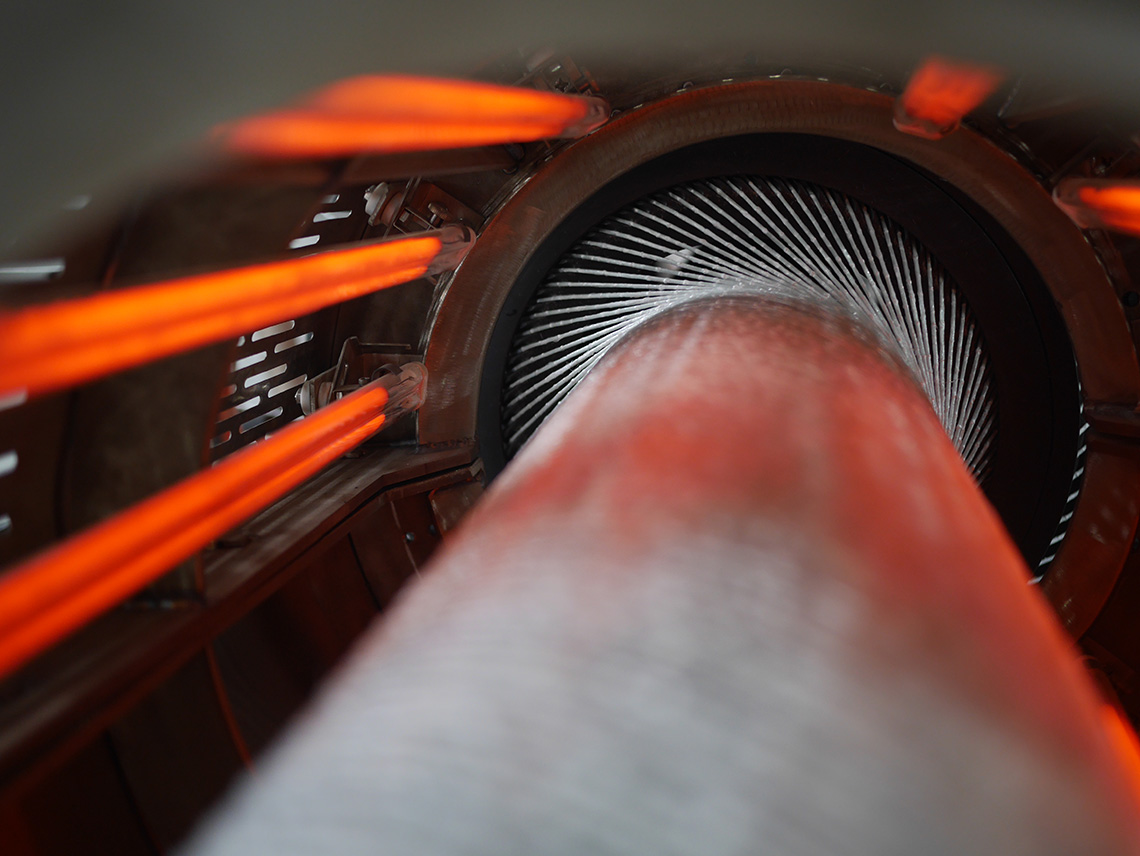

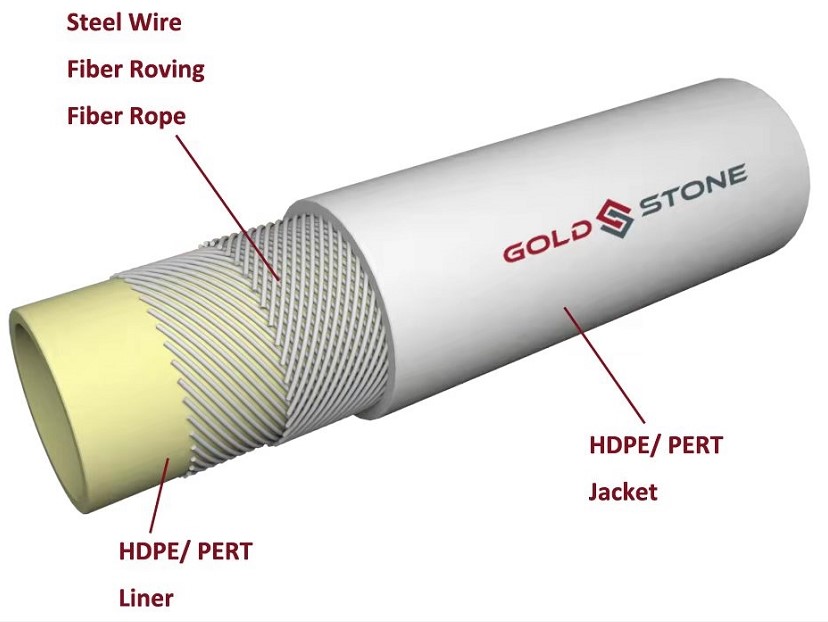

Goldstone’s RTP pipe technology uses thermoplastic impregnated glass fiber roving or rope as reinforcement.

Based on our years’ experience in steel wire reinforced pipes, Goldstone has developed its unique RTP pipe technology using impregnated glass fiber roving or rope, to achieve a fully bonded reinforced pipe process.

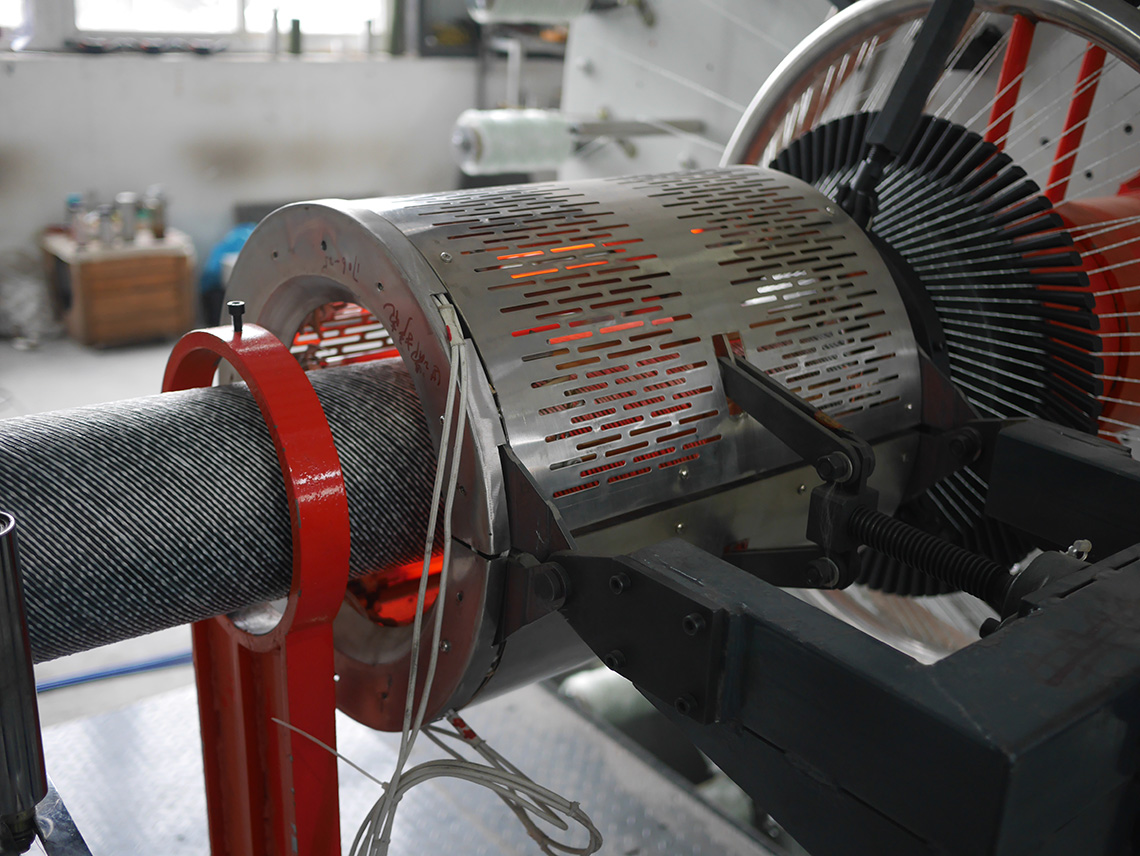

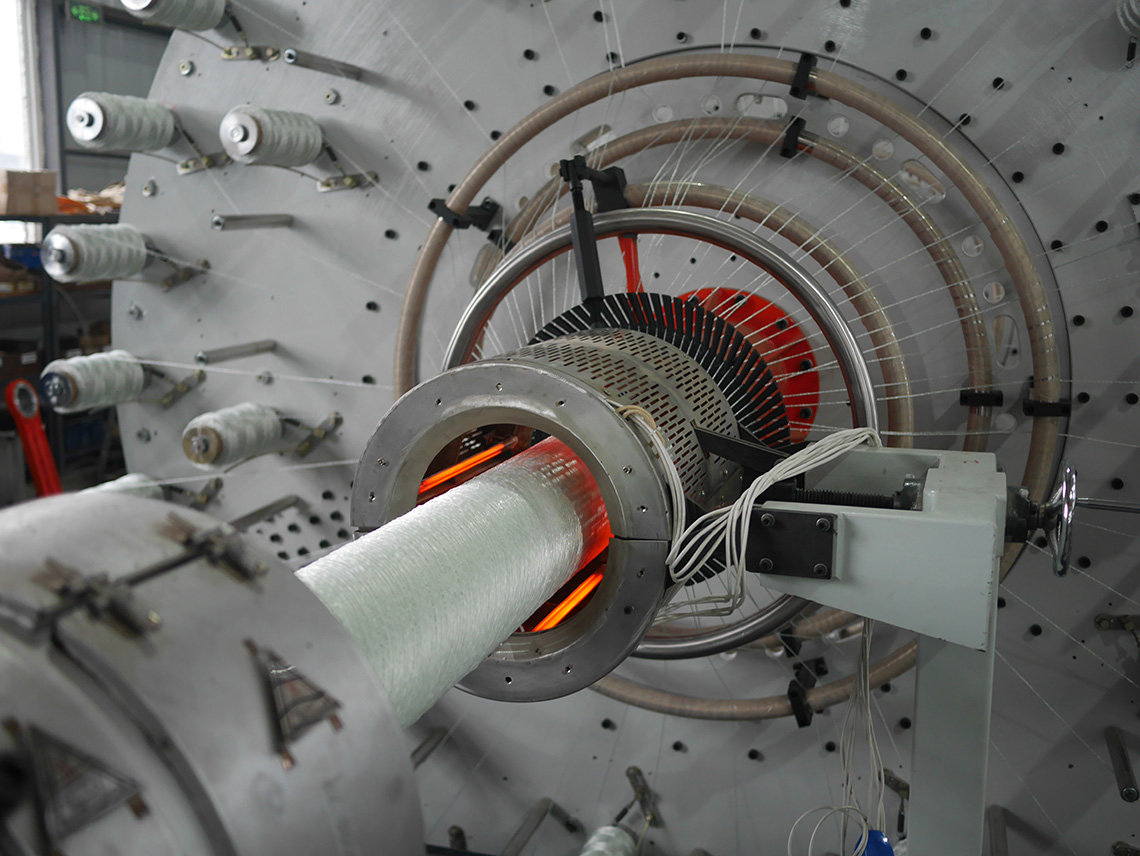

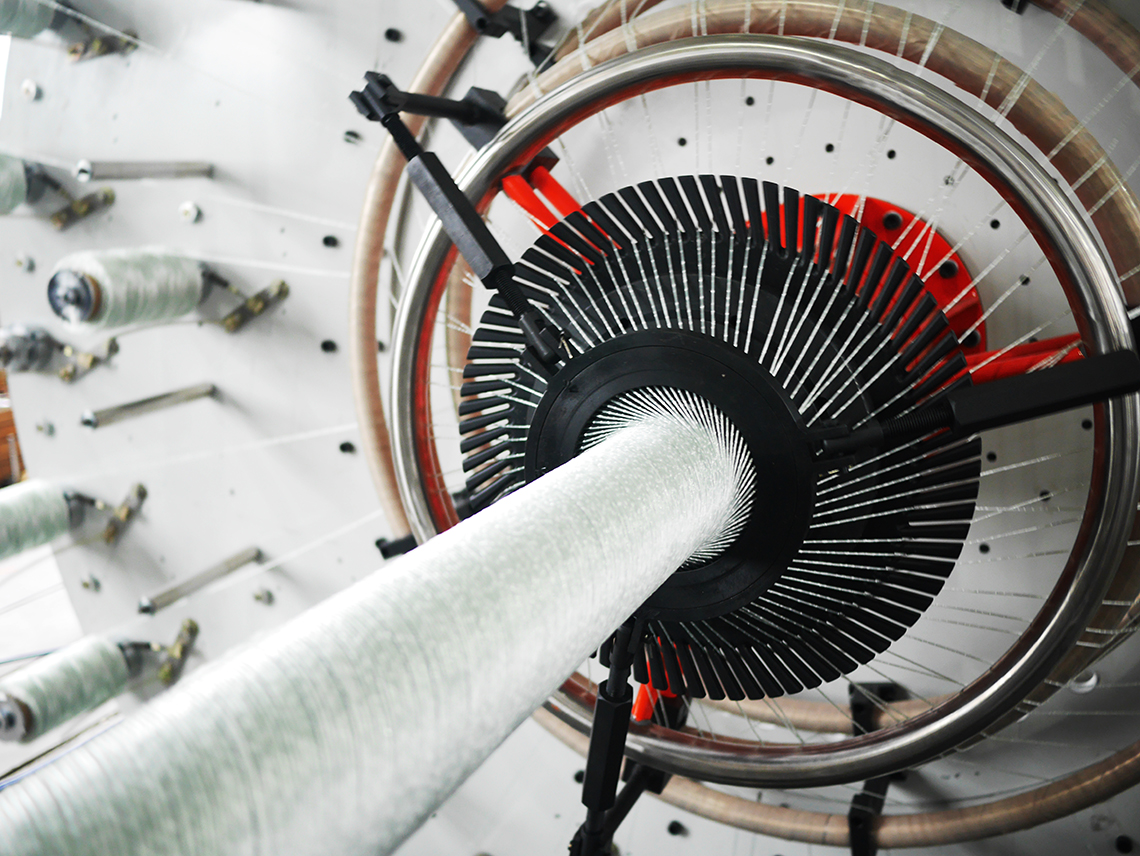

Goldstone developed the fully bonded fiberglass reinforced pipe structure and its processing machine. Using the adhesive resin to bond the liner pipe with reinforced layer, and the layers of glass fiber is melted and bonded each other, finally, an integral composite structure that can withstand high pressure is obtained.

The design of this reinforcing pipe comply with the provisions of API 15S and DNV-ST-F119 standards.

RTP is flexible and spool-able, and it is a good choice for transportation of oil, natural gas and other industries pipelines which need performance of high pressure, high corrosion, quick installation and easy maintenance.

Goldstone provides either impregnated glass fiber roving or tape wrapping technology and other potential combinations according to customer requirements for pipeline design.

Specifications for Glass Fiber RTP

| Pipe Size | 2″ | 3″ | 4″ | 5″ | 6″ | 8″ |

|---|---|---|---|---|---|---|

| Working Pressure | 750 psi 1500 psi 2250 psi 3000 psi Máx. 20 MPa |

750 psi 1500 psi 2250 psi Máx. 15 MPa |

750 psi 1500 psi 2250 psi Máx. 15 MPa |

750 psi 1500 psi Máx. 10 MPa |

750 psi 1200 psi Máx. 8 MPa |

750 psi 900 psi Máx. 6 MPa |

| Working Pressure | HDPE / 60 ℃ PERT / 70 ℃ |

HDPE / 60 ℃ PERT / 70 ℃ |

HDPE / 60 ℃ PERT / 70 ℃ |

HDPE / 60 ℃ PERT / 70 ℃ |

HDPE / 60 ℃ PERT / 70 ℃ |

HDPE / 60 ℃ PERT / 70 ℃ |