Glass Fiber Impregnated Tape Reinforced TCP Pipe Technology

Glass Fiber Tape Reinforced RTP Pipe

Fully Bonded TCP Pipe Technology

RTP & TCP: A Smarter Choice Than Traditional Steel Pipes

Say goodbye to the headaches of traditional steel pipes—Reinforced Thermoplastic Pipes (RTP) and Thermoplastic Composite Pipes (TCP) are transforming fluid transport for oil, gas, and infrastructure projects globally. These advanced thermoplastic solutions combine performance, efficiency, and cost savings in ways steel simply can’t rival.

When it comes to cost, RTP/TCP outshine steel. While their unit price is slightly higher, their total cost—pipe plus installation—cuts 5% to 30% off steel’s price tag. Why? They eliminate the need for welding crews, pipe benders, or heavy lifting equipment, and their lightweight design slashes transportation costs. Installation is equally streamlined: with continuous lengths up to 1,000m per coil and far fewer joints, crews can lay up to 1km in a single day, drastically reducing project timelines. Many projects even skip trenching, minimizing ground disruption and keeping operations on track.

A critical differentiator lies in life-cycle cost (LCC) performance—a metric encompassing initial procurement, installation, operation, maintenance, and end-of-service replacement costs. While RTP/TCP exhibit a marginally higher unit material cost than carbon steel pipes, their total LCC is 20%–40% lower over a 20-year service period.

Durability? RTP/TCP outlast steel here, too. Steel rusts and degrades quickly with corrosive fluids like brine or sour gas, requiring costly anti-corrosion coatings. RTP/TCP’s non-metallic structure resists corrosion naturally, with a service life that outlasts steel by 5 to 10 years.

Versatile enough for onshore oilfields, offshore platforms, fresh water pipelines, or rehabilitating aging steel systems, RTP/TCP adapt seamlessly to any scenario. For projects that prioritize speed, savings, and reliability, RTP/TCP aren’t just replacements for steel—they’re redefining the future of fluid transport.

RTP (Reinforced Thermoplastic Pipe)

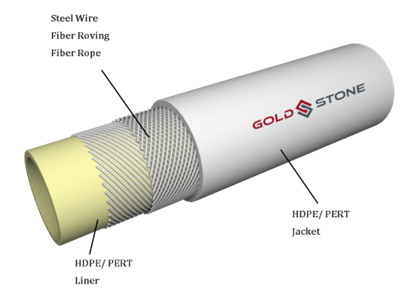

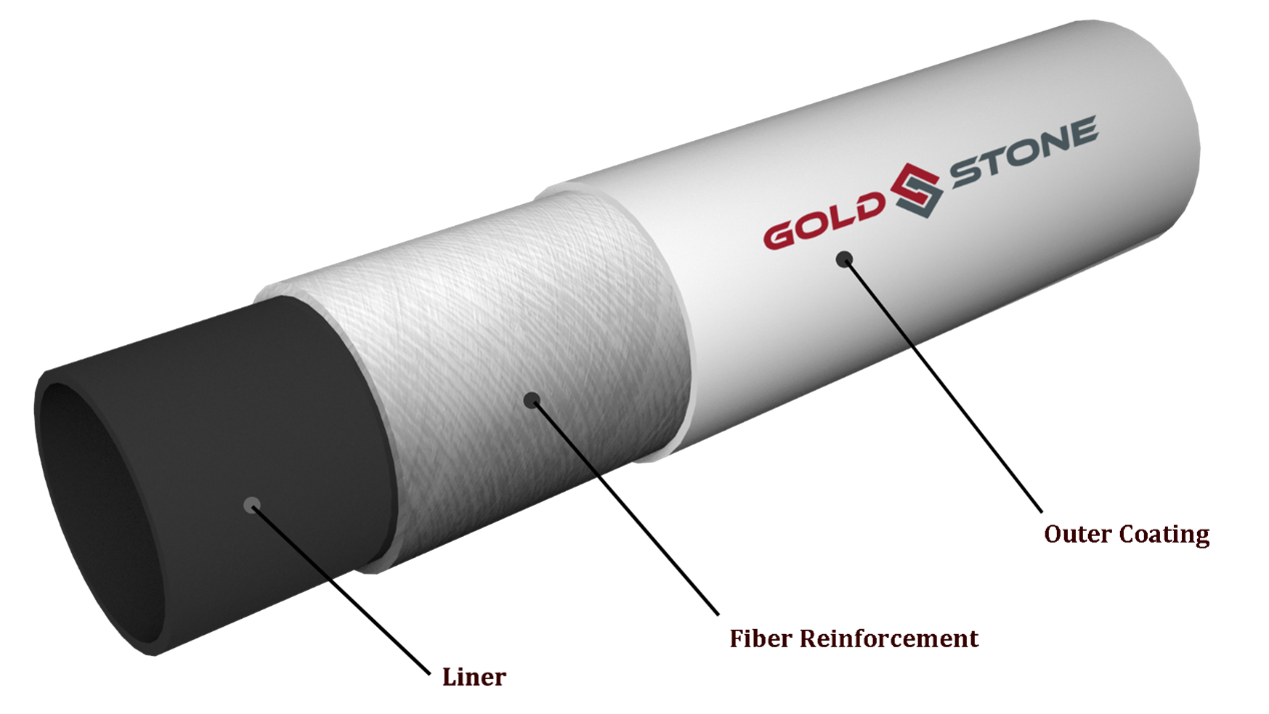

RTP is a multi-layer composite pipe engineered for fluid transport, consisting of three core components:

- Inner Liner: A thermoplastic tube (typically HDPE, PERT, PA or PVDF) that directly contacts the transported médium, providing chemical resistance and primary containment.

- Reinforcement Layer: A load-bearing structure composed of fiber tapes (glass, polyester, or occasionally aramid), designed to withstand internal pressure and axial loads. These fibers are partially impregnated with thermoplastic resin or bonded with adhesives to maintain layer cohesión.

- Outer Sheath: A thermoplastic layer (often HDPE) that protects the reinforcement from environmental damage (UV, abrasion, or moisture) during storage, installation, and service.

RTP layers are mechanically integrated—held together by friction, partial adhesive bonding, or limited thermal fusion—rather than forming a fully homogeneous structure.

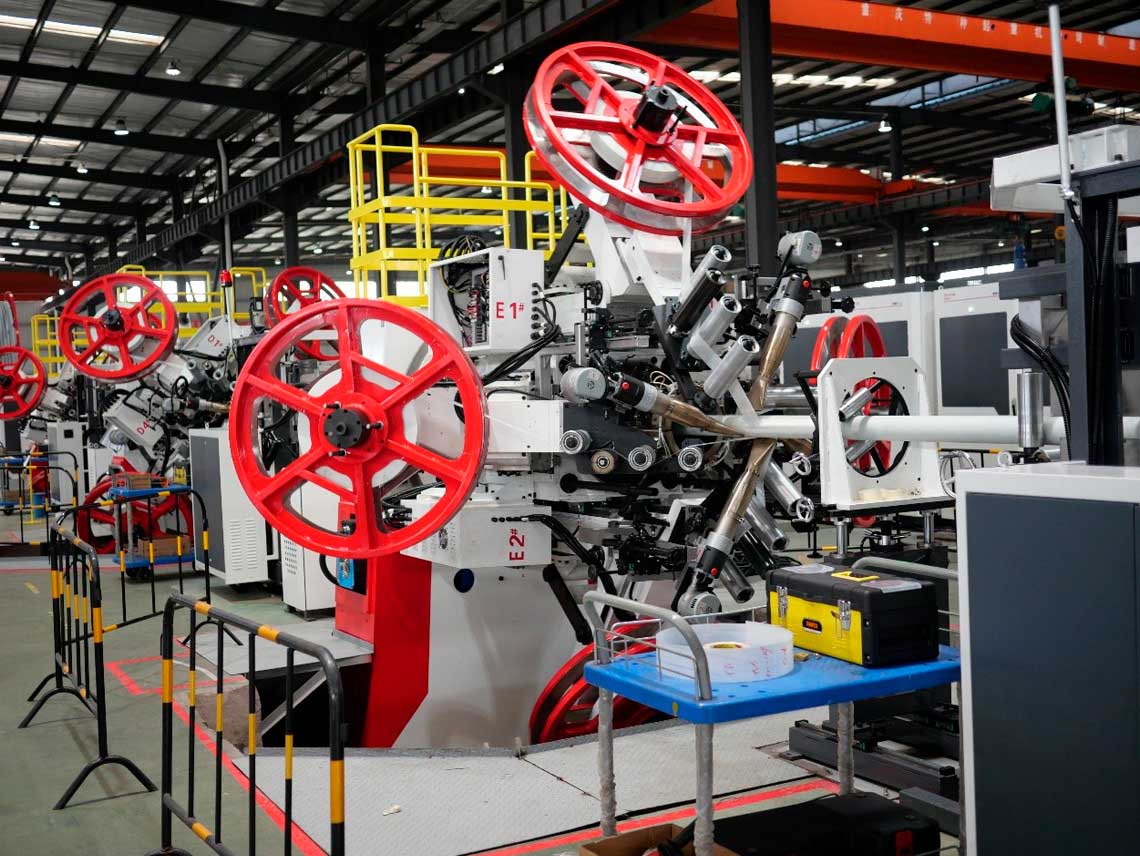

Technological Evolution: From RTP to TCP

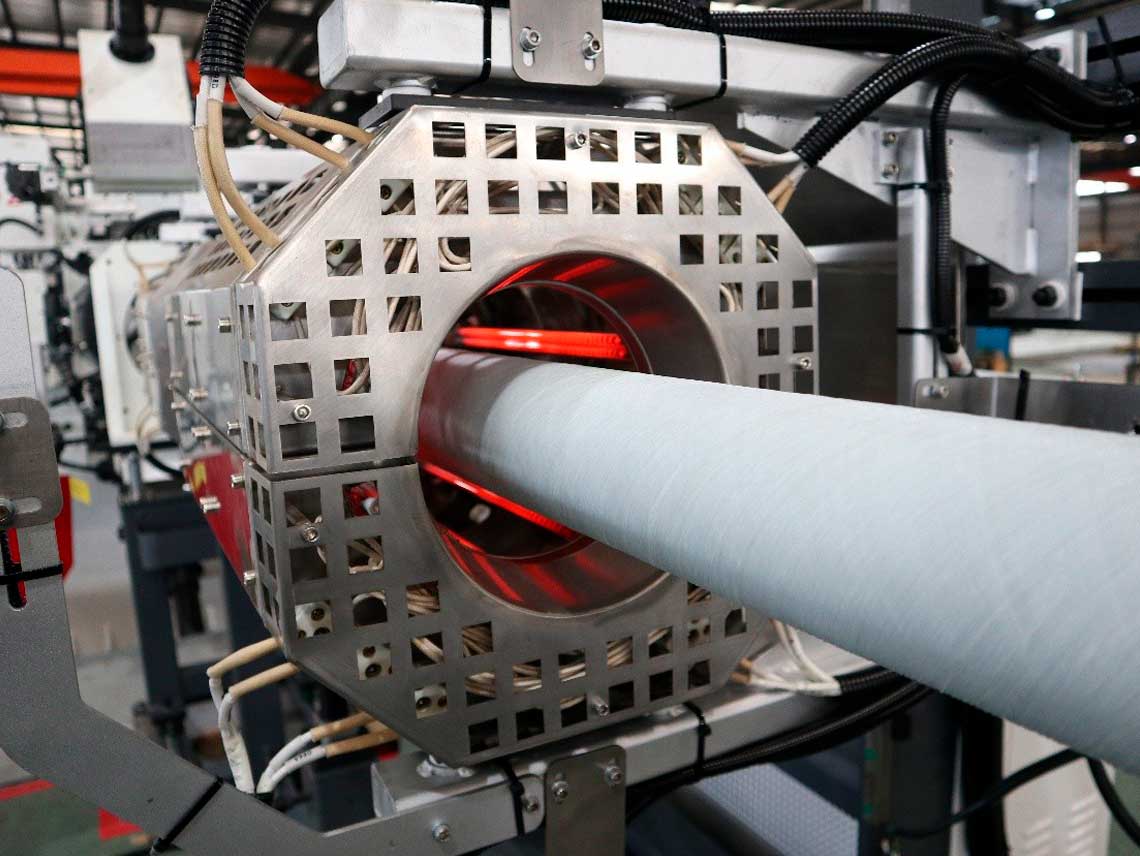

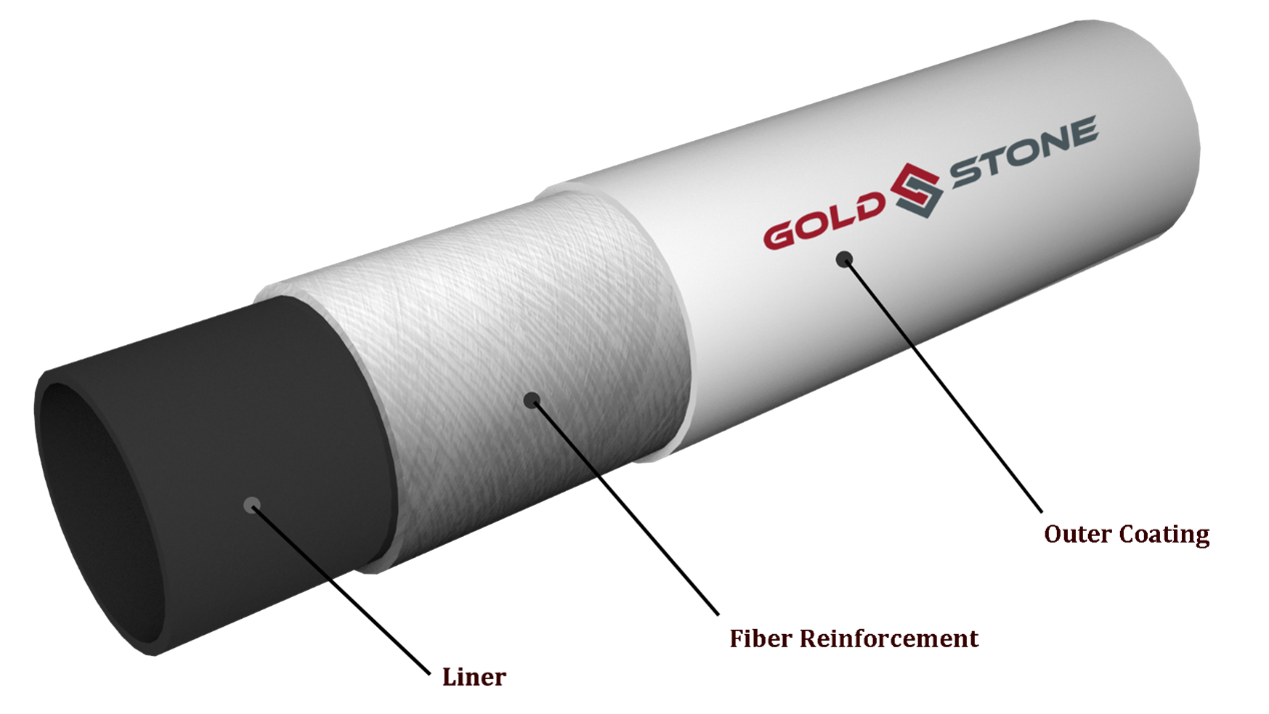

TCP is an advanced iteration of fiber reinforced RTP pipe, defined by its fully bonded, monolithic structure. It retains the three-layer framework but with critical material and structural upgrades,all layers—liner, reinforcement, and sheath—are melt-fused at the molecular level during manufacturing, eliminating discrete interfaces and forming a single integrated structure.

- Inner Liner: Same as RTP (thermoplastic for containment), but engineered for compatibility with high-temperature fusion processes.

- Reinforcement Layer: Fibers (glass, carbon, or aramid) are 100% impregnated with thermoplastic resin (e.g., modified PE) to eliminate voids. This forms a continuous, dense composite matrix.

- Outer Sheat: A thermoplastic layer fused to the reinforcement via thermal processing, creating a seamless transition between layers.

The reinforced glass fiber is completely impregnated with thermoplastic resin, and forms a fully bonded reinforcement layer. All layers, including the outer coating, are melt-fused together ensuring a bond between the layers that is as strong and durable as the base materials.

TCP represents a technological advancement over RTP, addressing RTP’s key limitations—particularly delamination risks and structural vulnerability—through its fully bonded, void-free design. While RTP remains suitable for low-to-medium pressure, non-critical applications, TCP is engineered for high-pressure, harsh-environment scenarios (e.g., deep oil & gas, chemical transport) where reliability and durability are paramount.

RTP and TCP are not competitive

While TCP offers superior performance for high-pressure, harsh-environment applications, it is not positioned to fully replace RTP—largely because RTP’s inherent characteristics align with the needs of specific scenarios where TCP’s advanced features are unnecessary or even disadvantageous. RTP remains the more suitable choice in the following contexts:

- Medium-to-Low Pressure Applications: For systems operating at moderate or low pressures (typically ≤10 MPa), RTP’s mechanical integration and partial reinforcement are more than sufficient to meet performance requirements. TCP’s full melt-fusion and void-free reinforcement, while technically superior, would introduce unnecessary over-engineering: the extra cost and complexity of TCP provide no meaningful benefit when the operational pressure does not demand its high load-bearing capacity. RTP, by contrast, delivers cost-effective reliability for these non-critical, low-stress use cases.

- Cost-Sensitive Projects: RTP’s simpler manufacturing process (e.g., no need for precise thermal fusion or 100% fiber impregnation) translates to 20–30% lower upfront material and production costs compared to TCP. This cost advantage is decisive for budget-constrained projects. In these cases, RTP becomes the more economically rational choice.

- Small Bending Radius: Spool-able is one of the most prominent advantages of reinforced thermoplastic pipes, a trait directly tied to its flexibility, which enables coiling into large reels in a reasonable minimum bending radius (MBR) for transportation. This coiled design allows for long-length pipe delivery (e.g., 500m–1000m per reel), significantly reducing on-site joint counts, shortening installation time, and lowering overall labor and logistics costs.RTP’s ductile fibers (e.g., polyester, with 15%–20% break elongation, same as steel) and flexible layered structure excel here: minor layer displacement disperses stress, avoiding brittle failure, its non-fully bonded layered structure, typically achieves an MBR of 16D–20D.TCP, by contrast, often cracks under such conditions because glass fiber offers a very low elongation at break (typically < 3%) cannot accommodate even small deformations, and the 100% impregnated glass fiber reinforcement and fully bonded manufacturing process create a rigid, solid-wall structure, while this solid-wall structure transfers external pressure directly to the reinforcement layer. In practice, TCP’s 20D–25D MBR often requires expensive shipment and trench widening or route redesign—making it impractical.

- Environments with High External Compressive Loads: RTP’s layered, mechanically integrated structure exhibits greater tolerance to localized external compressive forces (e.g., temporary soil compaction during construction, occasional heavy vehicle passage over shallowly buried pipes, or uneven ground settlement) compared to TCP’s rigid monolithic design. The discrete layers in RTP can absorb and distribute localized pressure without catastrophic failure: for example, if a section of the outer sheath is deformed by a heavy load, the inner liner and reinforcement layer may remain intact. TCP, by contrast, transfers external pressure more uniformly across its integrated structure—meaning localized compression could lead to more extensive damage (e.g., liner deformation or reinforcement matrix cracking) if the load exceeds its compressive limits. For pipelines in areas with unpredictable or frequent external loads (e.g., urban construction zones, unpaved rural roads), RTP’s flexibility and damage tolerance make it more resilient than TCP.

In conclusion, RTP and TCP are not competitive but complementary technologies. TCP addresses the high-performance needs of critical infrastructure (e.g., deep oil & gas, chemical transport), while RTP excels in cost-sensitive, low-to-medium pressure, or high-external-load scenarios. The optimal choice depends on aligning each technology’s strengths with the specific operational, budgetary, and environmental requirements of the project.

Benefits of Reinforced Thermoplastic Pipe for Oil and Gas Pipelines

Compared with steel pipe, the total cost (pipeline cost plus installation cost) is 5% to 30% cheaper than steel pipe. Although the unit cost of RTP/TCP is higher than that of steel, but the installation cost is considerably lower, because no pipe bender or welding crews are required, and less transportation equipment and cost are needed. The most valuable thing for customers is that the quick installation can save a lot of time for the project. In many cases, 1km of pipeline can be put in place in a day.

Reinforced thermoplastic pipe (RTP) has the highest strength to weight ratio and the longest continuous length of any commercial hose, using fewer pipe connections, so the product is cost-effective and easy to install.

The pipe can be used in a diverse range of applications: onshore and offshore; oil, gas, refined fluids, and brine; new installation or pull-through rehabilitation in aging existing steel pipeline systems. In many cases, no trenching is needed, minimizing cost and mitigating operational disruption.