Glass Fiber Impregnated Tape Reinforced TCP Pipe Technology

Glass Fiber Tape Reinforced RTP/TCP

Fully Bonded Composite Pipe Technology

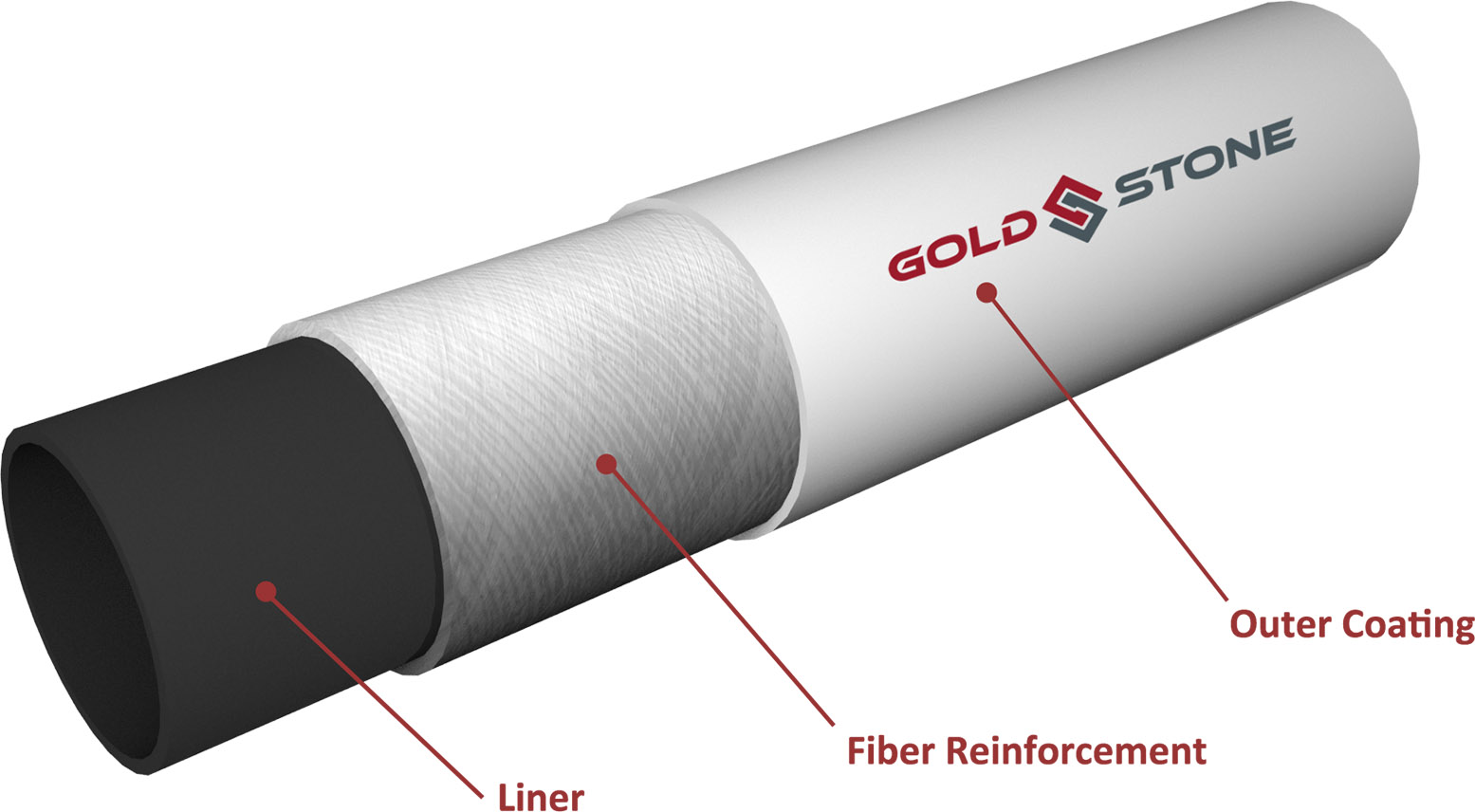

- RTP (Thermoplastic Reinforced Pipe) is a multi-layer composite pipe with polymer liner tube, reinforcing layer and thermoplastic sheath.

- TCP (Thermoplastic Composite Pipe) is a conception of fully bonded reinforced pipe, the layers of fiber reinforcement are melted and bonded to form as an integrated reinforced wall, and welded with liner tube and outer protective sheath.

Thermoplastic Composite Pipe (TCP) is a developing of the fiber reinforced thermoplastic pipe (RTP) technology. In this conception, the solid wall pipe consists of an inner liner, thermoplastic composite reinforcement layers and a protective outer coating. The reinforced glass fiber is completely impregnated with thermoplastic resin, and forms a fully bonded reinforcement layer. All layers, including the outer coating, are melt-fused together ensuring a bond between the layers that is as strong and durable as the base materials. TCP pipeline is free of corrosion due to its none metallic fiber reinforcement (e.g. glass, aramid, carbon), and it shows other advantages of superior structural integrity, safe and reliable, durable in case of cyclic loads.

Benefits of Reinforced Thermoplastic Pipe for Oil and Gas Pipelines

Compared with steel pipe, the total cost (pipe cost plus Installation) can range from 5 to 30% cheaper than steel line pipe. Although the unit cost of RTP/TCP is higher than steel, but the installation costs (workforce plus time) are considerably lower, because no pipe benders or welding crews are needed, and less handling equipment and traffic is required. The most valuable thing for customer is that the quick installation can save log of time for project, in many cases, 3000 feet of line can be put into place in 1 to 2 hours.

Compared with steel pipe, the total cost (pipeline cost plus installation cost) is 5% to 30% cheaper than steel pipe. Although the unit cost of RTP/TCP is higher than that of steel, but the installation cost is considerably lower, because no pipe bender or welding crews are required, and less transportation equipment and cost are needed. The most valuable thing for customers is that the quick installation can save a lot of time for the project. In many cases, 1km of pipeline can be put in place in a day.

Reinforced thermoplastic pipe (RTP) has the highest strength to weight ratio and the longest continuous length of any commercial hose, using fewer pipe connections, so the product is cost-effective and easy to install.

The pipe can be used in a diverse range of applications: onshore and offshore; oil, gas, refined fluids, and brine; new installation or pull-through rehabilitation in aging existing steel pipeline systems. In many cases, no trenching is needed, minimizing cost and mitigating operational disruption.

Specifications of GF RTP/TCP

| Dia. | Pipe ID | Pipe OD | Inner Tube Thick | Pipe Total Thick | Glass Layers | Cal. Burst Pressure | Working Pressure |

|---|---|---|---|---|---|---|---|

| 2″ | 50 mm | 73 mm | 4.5 mm | 11 mm | 12 | 50 MPa | 15 MPa (2250 Psi) |

| 2″ | 50 mm | 76 mm | 4.5 mm | 12.5 mm | 16 | 70 MPa | 20 MPa (3000 Psi) |

| 3″ | 75 mm | 106 mm | 6 mm | 15.5 mm | 16 | 52 MPa | 15 MPa (2250 Psi) |

| 3″ | 75 mm | 108 mm | 6 mm | 16.5 mm | 24 | 62 MPa | 20 MPa (3000 Psi) |

| 4″ | 100 mm | 132 mm | 7.5 mm | 16 mm | 12 | 33 MPa | 10 MPa (1500 Psi) |

| 4″ | 100 mm | 136 mm | 7.5 mm | 18 mm | 20 | 50 MPa | 15 MPa (2250 Psi) |

| 4″ | 100 mm | 140 mm | 7.5 mm | 20 mm | 24 | 59 MPa | 20 MPa (3000 Psi) |

| 6″ | 151 mm | 189 mm | 10 mm | 19 mm | 12 | 23.5 MPa | 8 MPa (1200 Psi) |

| 6″ | 151 mm | 194 mm | 10 mm | 21 mm | 18 | 32 MPa | 10 MPa (1500 Psi) |

| 6″ | 151 mm | 197 mm | 10 mm | 23 mm | 24 | 42 MPa | 12.5 MPa (1800 Psi) |

| 8″ | 200 mm | 244 mm | 11 mm | 23 mm | 16 | 24 MPa | 8 MPa (1200 Psi) |

| 8″ | 200 mm | 250 mm | 11 mm | 25 mm | 24 | 33 MPa | 10 MPa (1500 Psi) |

Remarks

- The pipe pressure is calculated by 0.3mm GF tape, Strength = 800 MPa.

- According to API 15S, Rating pressure =Burst Pressure / F

- Rating pressure is on temperature < 40 C (104F)

- If temperature = 65C (149F), then we take safe factor of 4-5.

- If temperature=82C (180F), then we take safe factor of 5-6.