Offshore RTP Pipe

Offshore RTP Pipe

Offshore Pipe Superiority

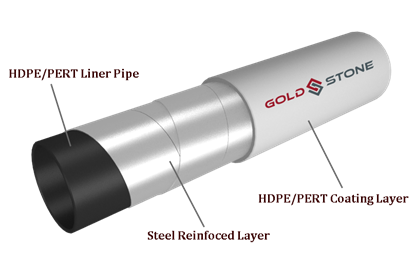

The steel reinforcement layer provides controlled weight distribution, balancing buoyancy in offshore waters and ensuring stable positioning even under mild offshore wind and wave conditions. This eliminates the need for additional buoyancy control devices (e.g., concrete weights) commonly used with lightweight plastic pipes, reducing offshore installation complexity.

The steel armored flexible pipe uniquely combines the best features of plastic and steel, high strength, corrosion resistance and flexible and durability. It is suitable for a variety of installation methods – trenching, plowing, surface, pipe rehabilitation, horizontal directional drilling, shallow water and more. With less transportation, handling equipment, and labor-work, the installation of the pipe can save 40% to 80% time and 35% to 65% less costly than jointed steel pipe. Because it has superior corrosion resistance and enhanced flow characteristics, the reinforced pipe also delivers operations and maintenance savings for superior value across the project life cycle.

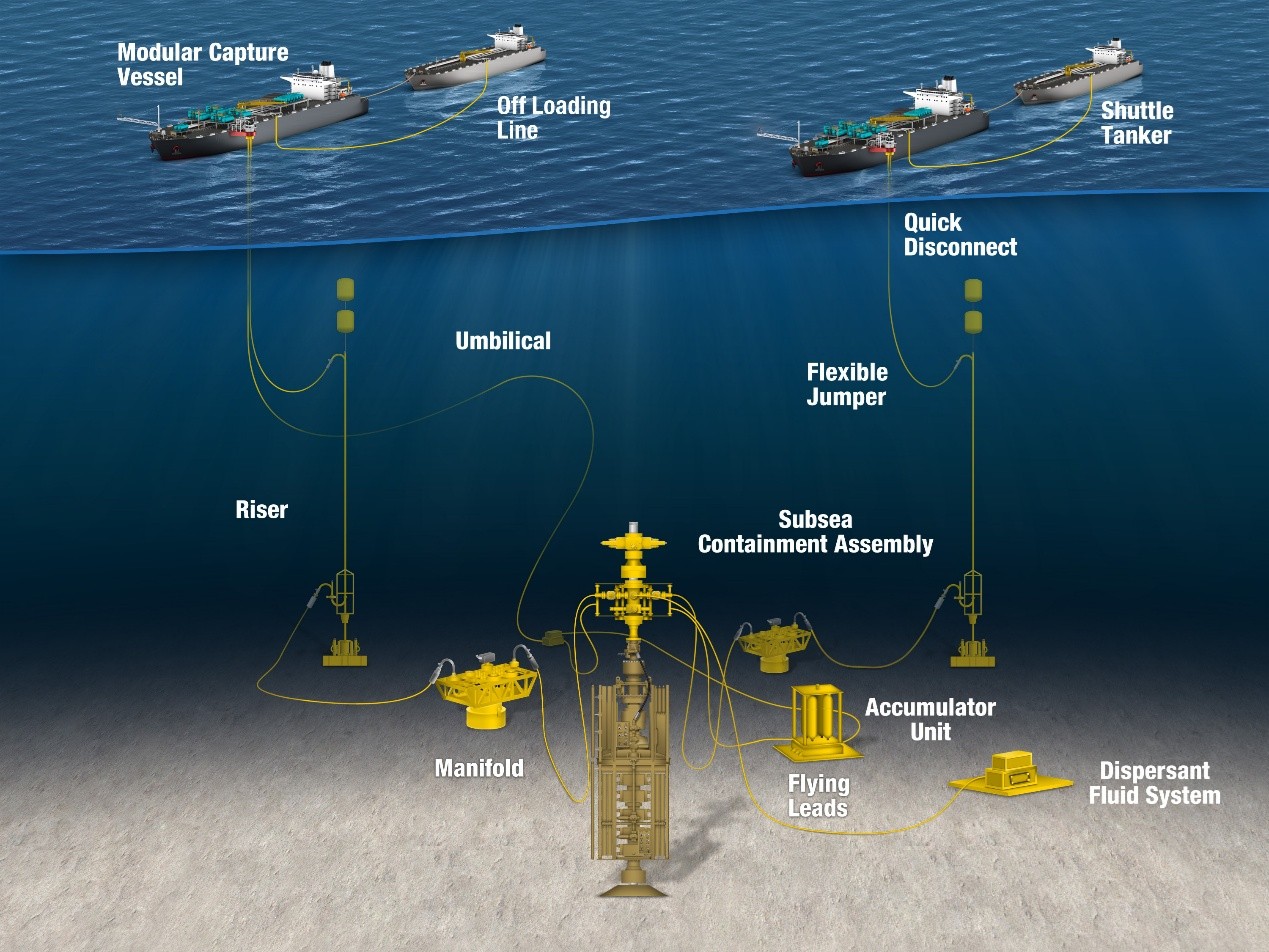

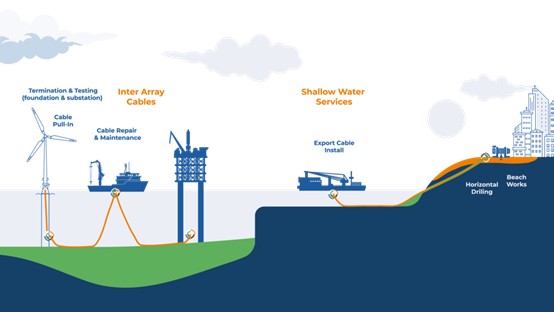

As a spooled flexible pipe, it enables seamless connection between offshore platform risers (vertical pipes connecting platform to seabed) and offshore flowlines (horizontal nearshore pipelines). Its non-bonded structure accommodates thermal expansion/contraction caused by offshore temperature fluctuations (seawater vs. platform fluid temperatures), avoiding pipe stress and leakage risks.

Offshore Installation Efficiency: It supports rapid offshore deployment via small-to-medium offshore vessels (no heavy-lift ships required for segmented steel pipes) and compatible installation methods (shallow offshore HDD, surface laying with offshore anchors), cutting offshore construction time by 45% vs. traditional jointed offshore steel pipes.

Offshore Advantages

This steel-armored flexible pipe uniquely integrates the strengths of plastic and steel, offering high mechanical strength, excellent corrosion resistance, superior flexibility, and long-term durability. Notably, it is exceptionally well-suited for subsea pipe installation: the substantial weight of its steel reinforcement layer provides optimal underwater stability, effectively mitigating buoyancy-induced displacement risks and ensuring secure positioning during subsea deployment — making it an ideal choice for shallow-water to medium-depth subsea projects.

As a spooled flexible pipe, it enables seamless connection between offshore platform risers (vertical pipes connecting platform to seabed) and offshore flowlines (horizontal nearshore pipelines). Its non-bonded structure accommodates thermal expansion/contraction caused by offshore temperature fluctuations (seawater vs. platform fluid temperatures), avoiding pipe stress and leakage risks.

It supports rapid offshore deployment via small-to-medium offshore vessels (no heavy-lift ships required for segmented steel pipes) and compatible installation methods (shallow offshore HDD, surface laying with offshore anchors), cutting offshore construction time by 45% vs. traditional jointed offshore steel pipes.