Polyester Fiber Reinforced RTP Pipes

Polyester Fiber Reinforced RTP Pipes

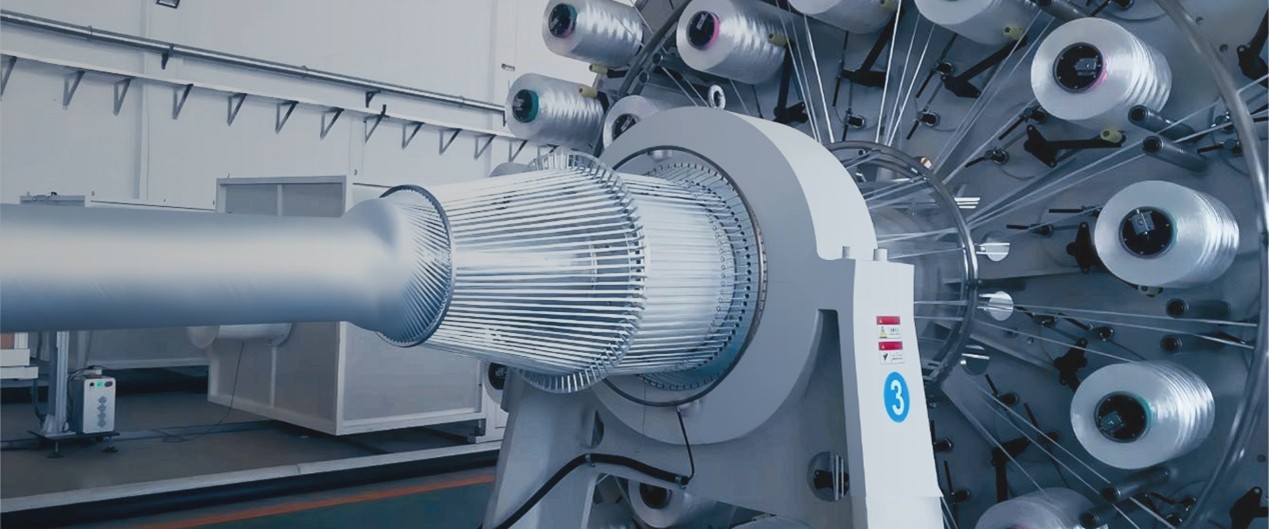

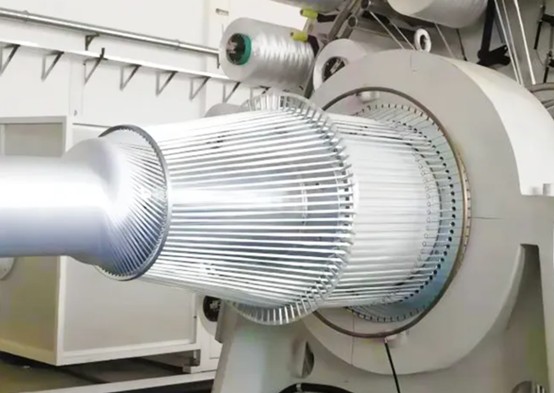

Polyester fiber-reinforced Reinforced Thermoplastic Pipe (RTP) stands as a pioneering and extensively utilized category within the RTP landscape. By synergizing the inherent benefits of thermoplastic matrices—such as corrosion resistance and flexibility—with the high tensile strength of polyester fiber reinforcement, this pipe system has solidified its pivotal role in a wide array of low-pressure fluid transportation applications across industries.

Core Technical Advantages

- Mature Application Ecosystem & Industry-wide Adoption: As one of the first RTP variants to enter practical service, polyester fiber-reinforced RTP has amassed profound application expertise over decades of industrial deployment. Rigorous market validation has underscored its consistent performance and operational reliability, cementing its status as a trusted solution in sectors ranging from municipal water supply to industrial process piping.

- Cost-Optimized Engineering Solution: Compared to alternative RTP configurations, this pipe type offers distinct cost competitiveness. Polyester fiber raw materials boast favorable price points, while the mature, scalable manufacturing processes—including continuous winding and extrusion—enable streamlined production workflows. This cost-efficiency makes it an optimal choice for projects with stringent budgetary constraints without compromising on essential performance metrics.

- Superior Suitability for Low-Pressure Scenarios: It is engineered to excel in low-pressure medium transportation applications, typically operating within the range of 750-1200 psi (5-8 MPa) and capable of withstanding pressures up to 1500 psi (10 MPa). Under such operating conditions, the pipe maintains structural stability, ensuring unobstructed and safe media conveyance while meeting the core requirements of most low-pressure pipeline infrastructure projects.

Technical Considerations & Limitations

- High-Temperature Performance Boundary: Polyester fiber exhibits substantial strength degradation when exposed to temperatures exceeding 60℃. This thermal sensitivity restricts its application scope, precluding its use in scenarios involving media temperatures above this threshold. In high-temperature environments, the pipe’s structural integrity and load-bearing capacity may be significantly compromised, introducing considerable safety risks.

- Circumferential Pressure Resistance Constraints: Early-generation polyester fiber-reinforced RTP predominantly features non-adhesive constructions. With a breaking elongation of 15-20%, polyester fiber may induce pipe expansion under specific conditions. The absence of inter-fiber bonding exacerbates this issue by altering the fiber winding angle, which in turn modifies the pipe’s overall pressure-bearing capacity. Additionally, pipe bending, expansion, and contraction can disrupt the positional and angular stability of the fiber windings, failing to sustain a consistent winding structure—ultimately limiting the pipe’s circumferential pressure resistance and precluding its use in high-pressure transportation applications.

- Advancements and Remaining Constraints: In recent years, Goldstone has developed enhanced RTP pipes using polyester fiber tapes, optimizing the structure of polyester fiber-reinforced pipes into a semi-adhesive type. This improvement has increased the pressure rating of the pipes. However, limited by the inherent performance of the material itself, it still cannot achieve the temperature resistance and high pressure capacity of other adhesive-structured reinforced pipes.

Conclusion

Polyester fiber-reinforced RTP pipes deliver exceptional value in low-pressure, ambient-temperature transportation scenarios, leveraging their mature technology platform and cost-effectiveness. However, their limitations in high-temperature resilience and circumferential pressure-bearing capacity necessitate careful evaluation against project-specific parameters during material selection. With ongoing advancements in fiber-matrix bonding technologies and polyester material modification, this pipe system holds tremendous potential for performance enhancement—paving the way for expanded application boundaries in the future industrial landscape.