Crimping and Swaging Machine

Compression Fittings for RTP/TCP

Why Outer Compression?

RTP’s composite structure (thermoplastic + fiber reinforcement) makes it unsuitable for heat-based joining (e.g., welding, which can melt the liner or degrade fibers) or traditional solvent bonding (ineffective on reinforced layers). Outer compression avoids heat or chemicals, preserving the pipe’s integrity.

In RTP outer compression, the goal is to compress an outer fitting (typically a metal sleeve) around the pipe’s outer jacket, transferring force through the jacket to the reinforcement layer and inner liner. This compression creates a [mechanical seal] via friction and a [structural lock] to resist axial pull-out, ensuring the joint can withstand internal pressure and external loads.

Crimping the fittings:

- An outer sleeve (metal, e.g., stainless steel, or high-strength plastic) designed to deform under pressure.

- A gripping ring or serrated insert (to bite into the pipe’s outer surface for anti-pull-out resistance).

- A sealing element (e.g., O-ring or elastomeric gasket) to prevent fluid leakage between the fitting and pipe.

Crimping and Swaging

The Crimping and Swaging are two kinds of very necessary method to install the end fittings or connector on the flexible RTP/TCP pipe by mechanical compression. Goldstone can supply the customized crimping machine and swaging machine for RTP/TCP project. Currently swaging process is becoming more and more popular because its compression is more uniform and smooth. We designed a multiple functional automatic swaging machine, which is especially suitable for large-diameter RTP / TCP, and creatively combined internal expansion and external compression in one machine.

Crimping from outside

Swaging from inside

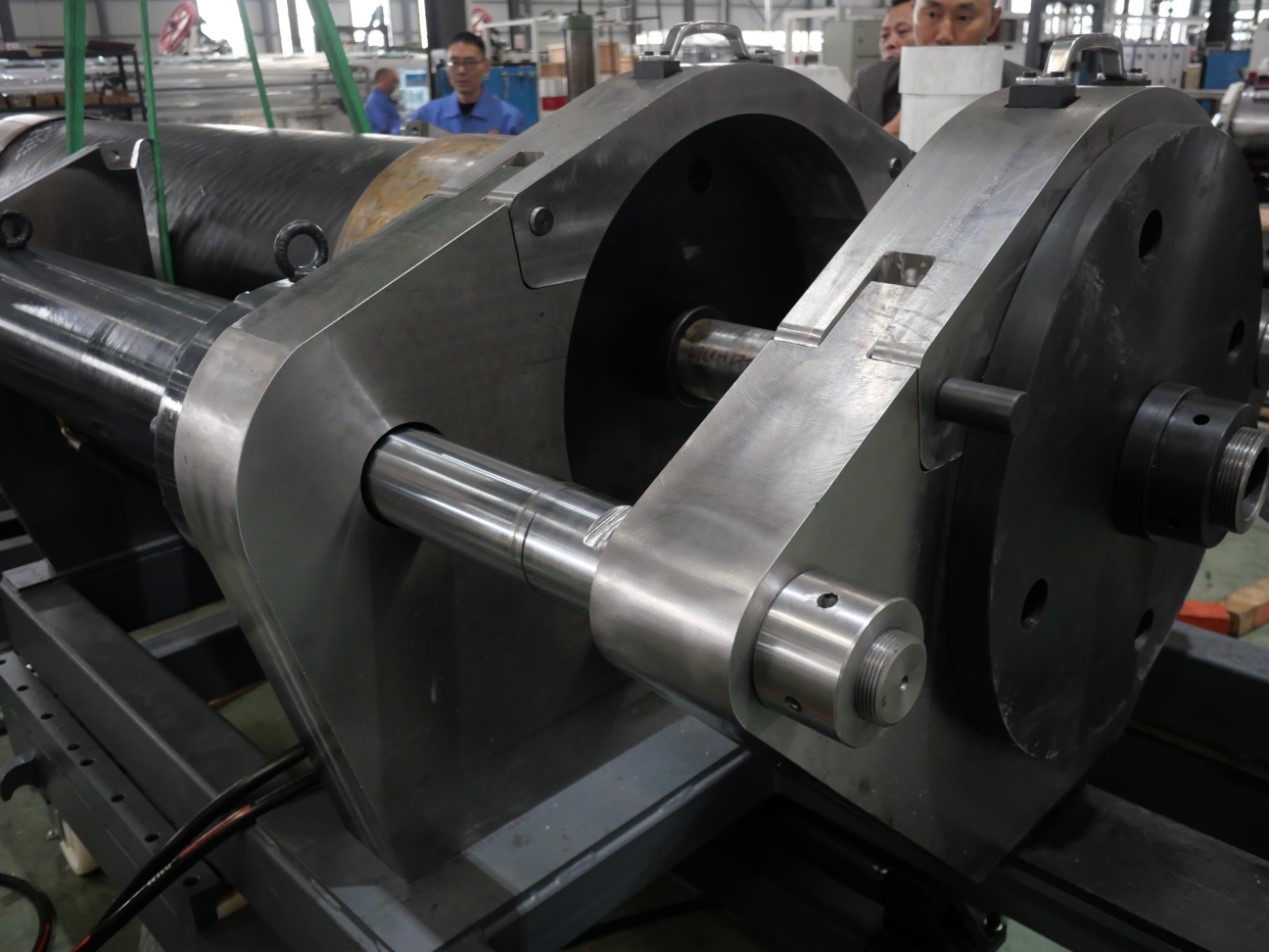

Crimping Machine

Crimping machines use mechanical radial compression (avoiding heat/welding to protect the thermoplastic liner and fiber reinforcement). First, insert the RTP end into a matching metal crimp fitting, then align the machine’s segmented dies with the fitting’s outer surface to ensure concentricity. The hydraulic driven dies then close radially, applying uniform pressure to the metal fitting. As the metal fitting deforms inward, it clamps the RTP’s outer jacket tightly, transferring force to the fiber reinforcement and inner liner—making the liner fit the fitting’s inner structure. The fitting’s grooves embed into the pipe layers to form a mechanical interlock. Once reaching preset pressure, the dies retract, leaving the deformed fitting permanently locked to the RTP, creating a leak-tight seal against internal pressure and an anti-pull structure to prevent axial disengagement

- Pipe Dia.: 2-6 inch

- Clamping Force: 1300 ton

- System Pressure: 30 MPa

Swaging Machine

A swaging machine, also known as a radial forging machine, is a precision metalworking tool that uses radial pressure to reduce the diameter (compress) or expand the inner bore (expand) of a steel fitting by applying controlled force through dies.

Unlike the crimping machine, the swaging process enables steel fittings to undergo stepless and continuous deformation, resulting in more uniform pressure acting on the pipe. Therefore, this process is particularly suitable for glass fiber-reinforced TCP Pipe, especially since fiberglass has a narrow allowable deformation range.

External Compression Swaging

The dies compress the outer surface of the workpiece, reducing its diameter.

Internal Expansion Swaging

An internal mandrel or expander is pushed through the workpiece to increase its inner diameter.

Internal swaging can provide grip to hose material, and be used to improve flow area through tubing or hoses. In fact, this form of swaging increases the size of applicable items, and plays a key role in lowering the risks of bacteria accumulating near the end of the hose or tube. It also helps to reduce turbulence by providing a firm mechanical adhesiveness and bond.