Crimping and Swaging Machine

Crimping and Swaging

The Crimping and Swaging are two kinds of very necessary method to install the end fittings or connector on the flexible RTP/TCP pipe by mechanical compression. Goldstone can supply the customized crimping machine and swaging machine for RTP/TCP project. Currently swaging process is becoming more and more popular because its compression is more uniform and smooth. We designed a multiple functional automatic swaging machine, which is especially suitable for large-diameter RTP / TCP, and creatively combined internal expansion and external compression in one machine.

Crimping from outside

Swaging from inside

Crimping Machine

- Pipe Dia.: 2-6 inch

- Clamping Force: 1300 ton

- System Pressure: 30 MPa

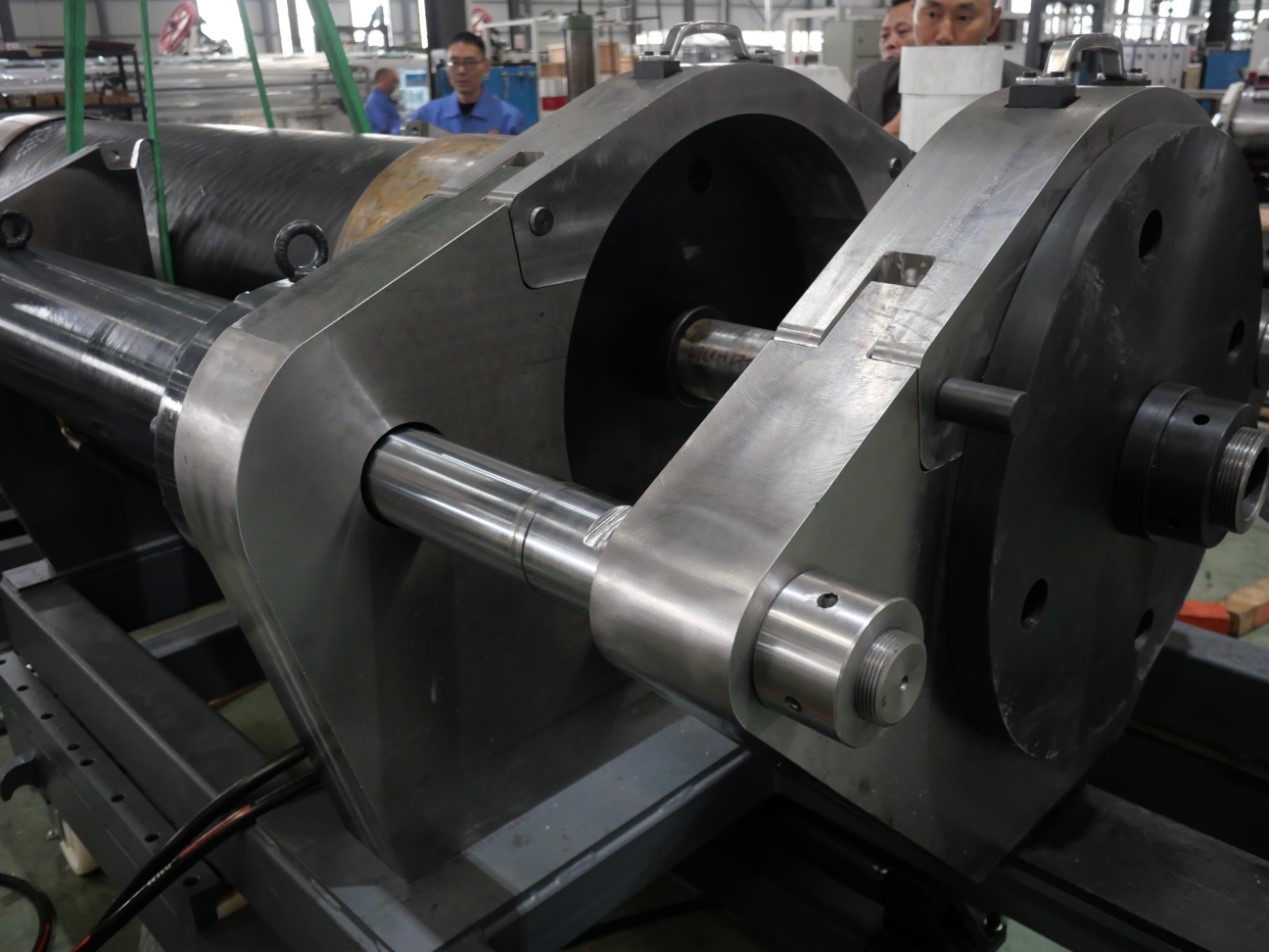

Swaging Machine

What is Swaging Operation?

Swaging is the action-oriented process for shaping a swage. A swage is the shaped tool used to transform an object’s shape into the desired form by bending or shaping. The process can alter the diameter of rods, hoses and/or tubes.

Swaging process can be classified as internal, external or combination. Goldstone suggest to use combination for large diameter RTP/TCP pipe, for small diameter pipe or connection in the field can use external swaging operation. The steel fitting design is not the same according to the different swaging method.

Internal swaging can provide grip to hose material, and be used to improve flow area through tubing or hoses. In fact, this form of swaging increases the size of applicable items, and plays a key role in lowering the risks of bacteria accumulating near the end of the hose or tube. It also helps to reduce turbulence by providing a firm mechanical adhesiveness and bond.