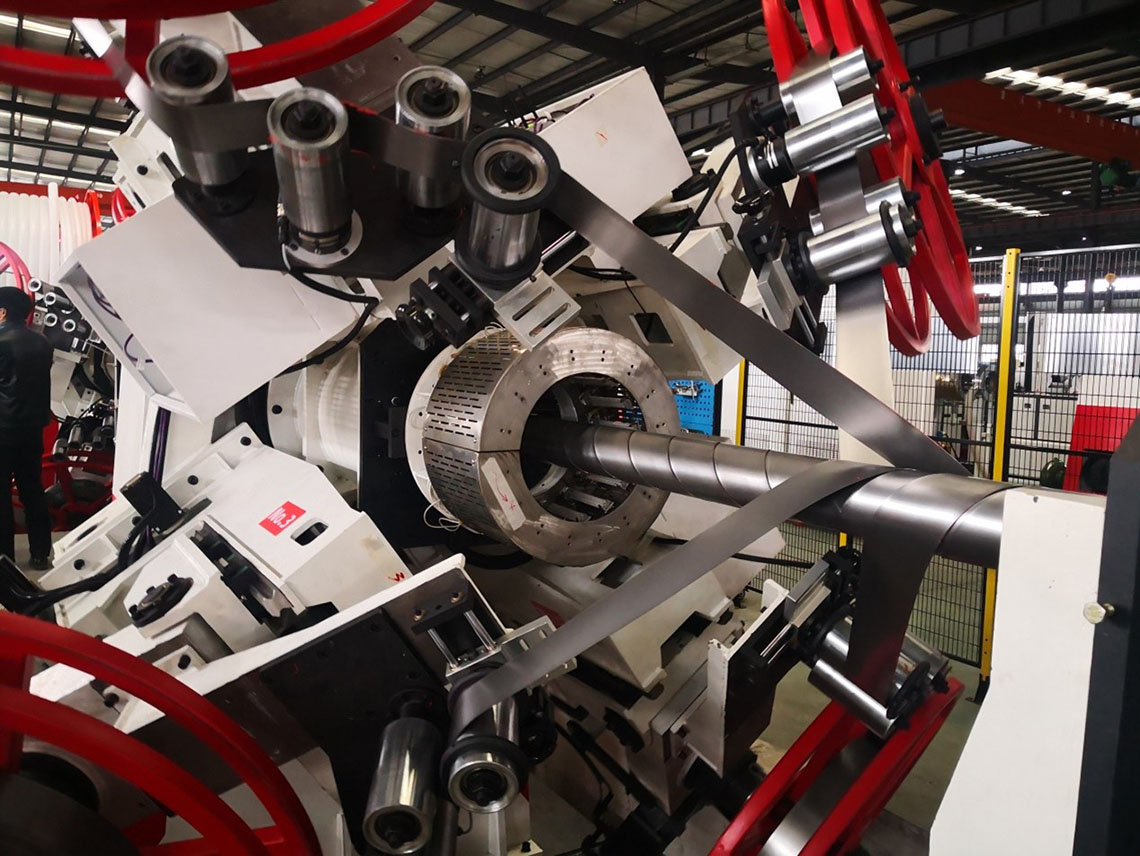

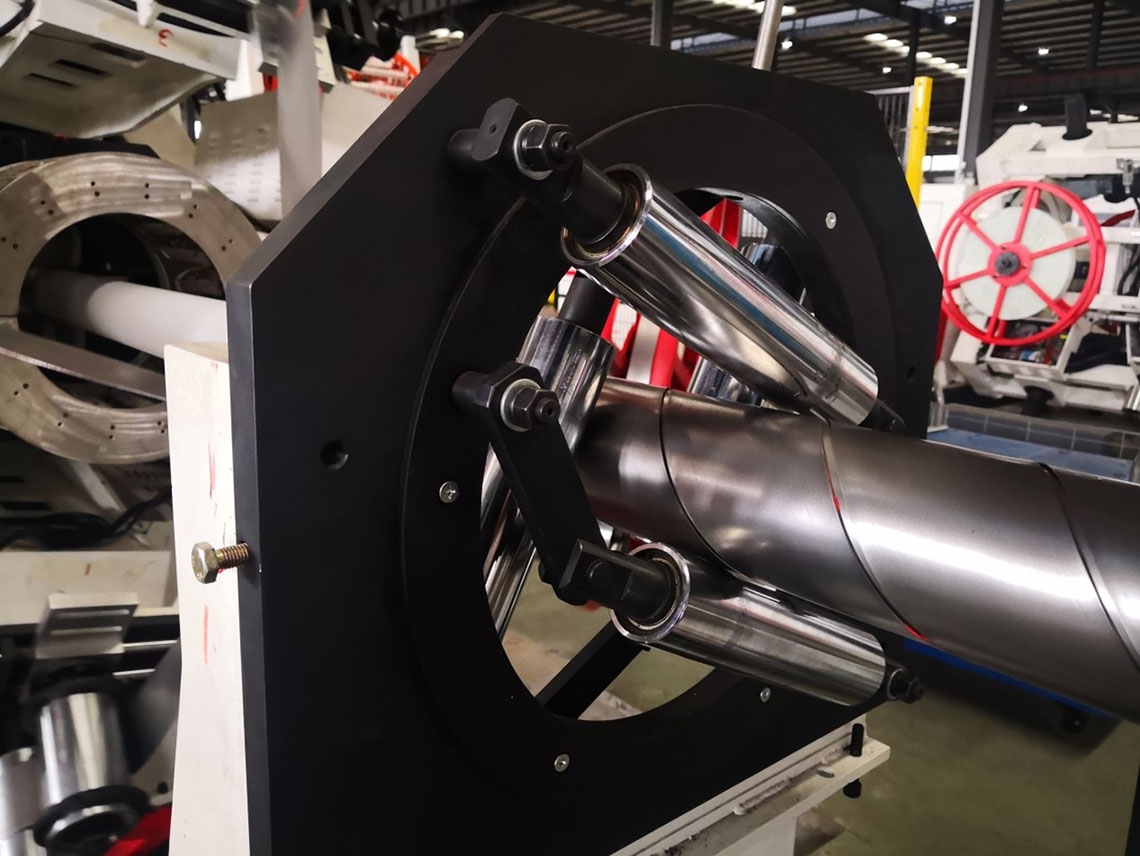

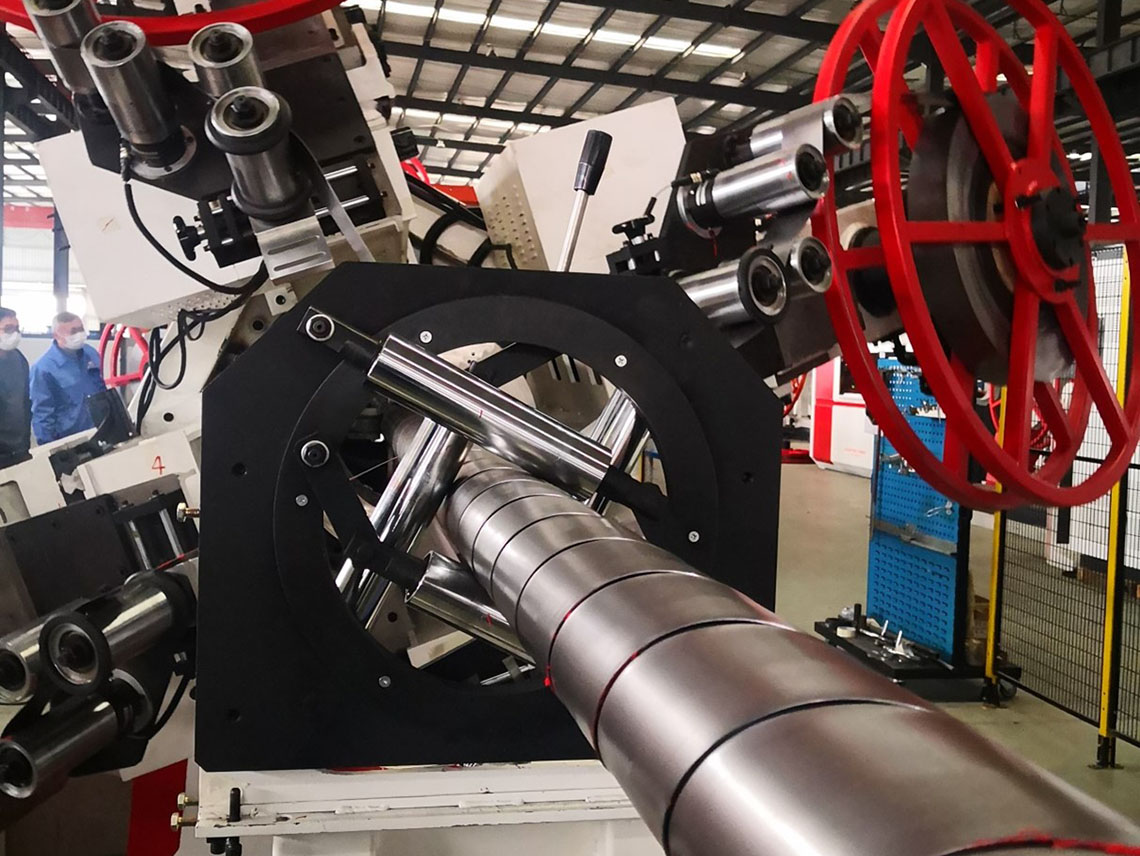

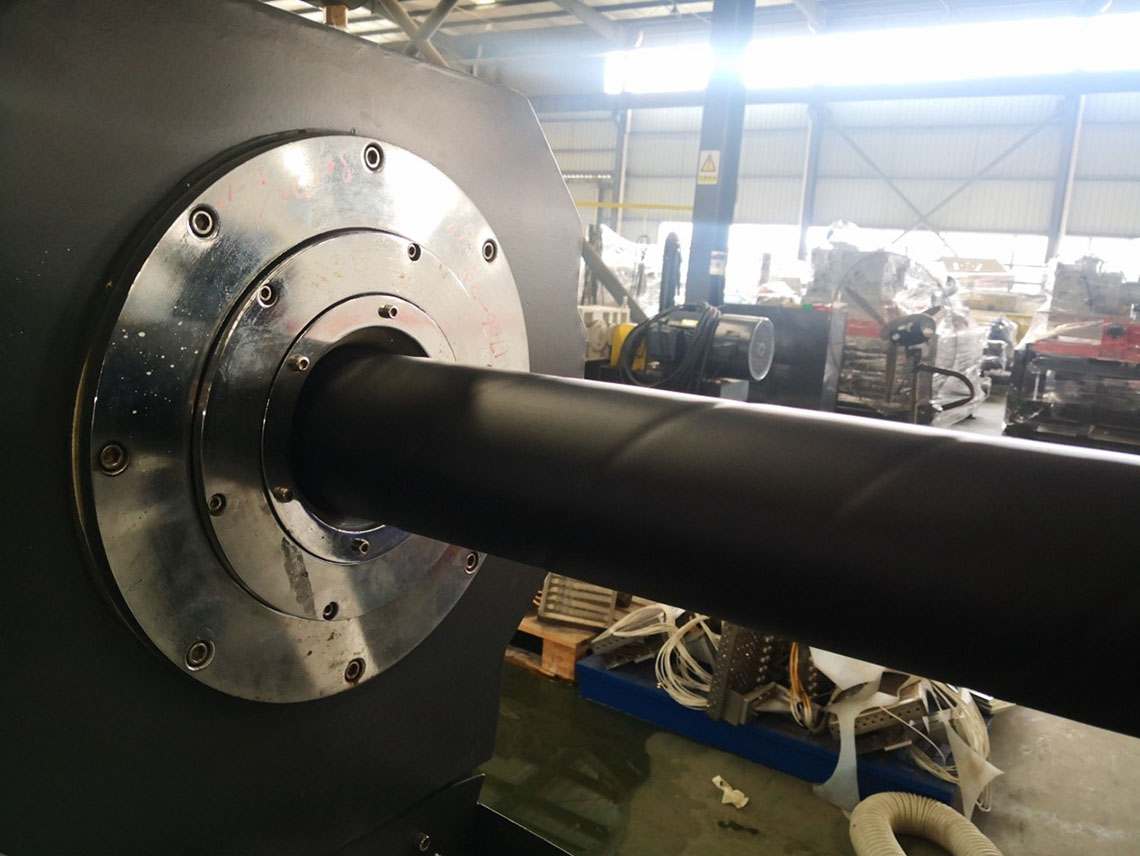

RTP tube technology reinforced with carbon steel strips

Steel Tape Reinforced Non-Bonded RTP Pipe Production

The Steel Tape Reinforced Flexible Spooled Pipe is a dedicated non-bonded Reinforced Thermoplastic Pipe (RTP). This type of RTP pipe is a highly mature technical solution engineered to enhance pressure resistance and impact resistance. With over 30 years of validated performance in the oil and gas industry, it serves as a reliable choice for offshore pipes (risers, flowlines).

Fully compliant with the stringent standards of API-17J, this product adheres to global oil and gas industry safety and performance benchmarks.

1. Offshore Pipe Superiority

Optimized for offshore oil & gas operations (nearshore to shallow offshore areas), it meets the rigorous demands of offshore pipe applications.

The steel reinforcement layer provides controlled weight distribution, balancing buoyancy in offshore waters and ensuring stable positioning even under mild offshore wind and wave conditions. This eliminates the need for additional buoyancy control devices (e.g., concrete weights) commonly used with lightweight plastic pipes, reducing offshore installation complexity.

Moreover, as a non-bonded RTP structure, it exhibits enhanced adaptability to thermal expansion and contraction (a common challenge in subsea/onshore environments), further reducing the risk of pipe deformation or failure.

2. Mining Slurry Transportation Breakthrough

Recent field tests validate this pipe’s exceptional suitability for mining slurry transportation (e.g., tailings, mineral concentrate). As a continuous spooled product, it skips on-site jointing, bends over rough mining terrain (hills, gravel), and cuts installation time by over 50% vs. segmented pipes. The additional abrasion-resistant layer integrated into the plastic composite liner provides superior resistance to slurry particle scouring, while the thermoplastic base material withstands acidic and alkaline mining wastewater. Together, these enhancements extend the pipeline’s service life by 2–3 times compared to conventional options and slash maintenance and downtime costs.

Cost & Efficiency Advantages

Compared to traditional jointed steel pipes, the flexible composite pipe minimizes transportation requirements, handling equipment, and labor input, resulting in remarkable savings.

| Scenarios | Installation Time Reduction | Installation Cost Reduction | Key Drivers |

|---|---|---|---|

| Offshore Oil & Gas | 40%–80% | 35%–65% | Less heavy-lift equipment, fewer offshore joints |

| Mining Slurry | >50% | 40%–60% | No on-site jointing, reduced labor/materials |

Cross-Industry Installation Methods

The pipe supports multiple installation approaches to meet varied project needs, including:

- Trenching

- Plowing

- Surface laying

- Pipe rehabilitation

- Horizontal Directional Drilling (HDD)

- Shallow water & subsea installation

- And other customized scenarios

Tailored to offshore and mining operational needs, it supports versatile installation:

- Offshore: Shallow offshore HDD, offshore platform riser connection, nearshore surface laying (with anchors).

- Mining: Plowing, surface laying, short-distance HDD (cross-mining roads).

- General: Trenching, pipe rehabilitation (oil & gas/municipal)