Steel Cord Tape Reinforced RTP Tube Technology

High Strength Steel Cord Tape Reinforced Pipe Technology

Reinforced thermoplastic pipes (RTP) utilizing glass fiber or polyester fiber reinforcement are primarily limited to small-diameter applications. This constraint arises because high-pressure, large-diameter RTP would require the use of multiple layers of thin impregnated fiber tape—typically 30 to 50 layers. The high number of reinforcement layer wraps creates two critical challenges: it impairs interlayer bonding integrity, and it significantly prolongs the pipe’s manufacturing cycle (as such a large number of layers cannot be applied in a single production pass). Furthermore, such a high volume of reinforcement makes the pipe much harder to coil, which undermines its inherent flexibility advantage—a key characteristic of traditional RTP.

However, in some critical scenarios where large-diameter plastic composite pipes are needed to replace conventional steel pipes—often to mitigate steel’s inherent drawbacks (corrosion susceptibility, heavy weight, and high installation/maintenance costs)—high-strength synthetic fibers (e.g., aramid or carbon fiber) have failed to gain widespread adoption. Their prohibitively high material and processing costs render them economically unfeasible for most oil and gas operators, who are the primary end-users of large-diameter onshore pipelines.

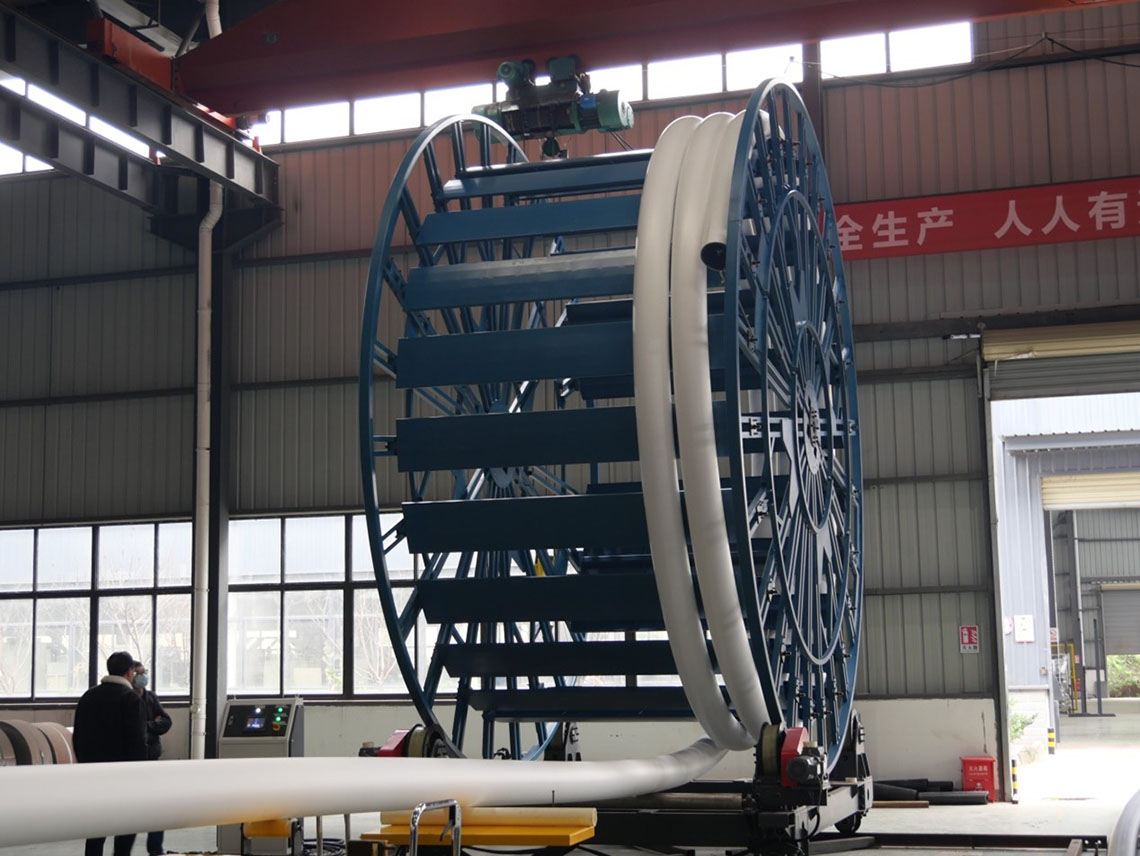

To address this critical performance-cost gap, Goldstone has developed a cost-effective yet high-performance alternative: Steel Cord-Reinforced RTP Pipe Technology. This innovation integrates the high pressure-bearing capacity of steel with the corrosion resistance, flexibility, and lightweight properties of thermoplastics.

The high-strength steel cord is manufactured by twisting multiple fine steel wires, delivering excellent flexibility and high monofilament strength. Its unit tensile strength exceeds 3000 MPa—far surpassing the 800 MPa of impregnated glass fiber tape. For instance, a 1.0 mm-diameter steel cord offers a tensile strength of approximately 1900–2000 N, equivalent to that of 900 tex aramid fiber; in contrast, 1600 tex (≈1.1 mm) glass fiber or polyester fiber only provides 800–900 N of tensile strength. Thus, steel cord emerges as a cost-effective reinforcing material to replace expensive synthetic fibers in large-diameter composite pipes.

1. Structural Design and Manufacturing Process

To maximize the performance of steel cord reinforcement, the steel cord-reinforced RTP pipe adopts a three-layer co-extruded composite structure, with each layer optimized for functional synergy:

- Inner Liner: Extruded from high-density polyethylene (HDPE) or polypropylene random copolymer (PPR) with high melt flow rate. This layer ensures excellent chemical resistance to oil, gas, and corrosive media (e.g., formation water, sewage), while maintaining a smooth inner wall to minimize fluid friction loss (friction coefficient <0.015, lower than that of steel pipes by 30%).

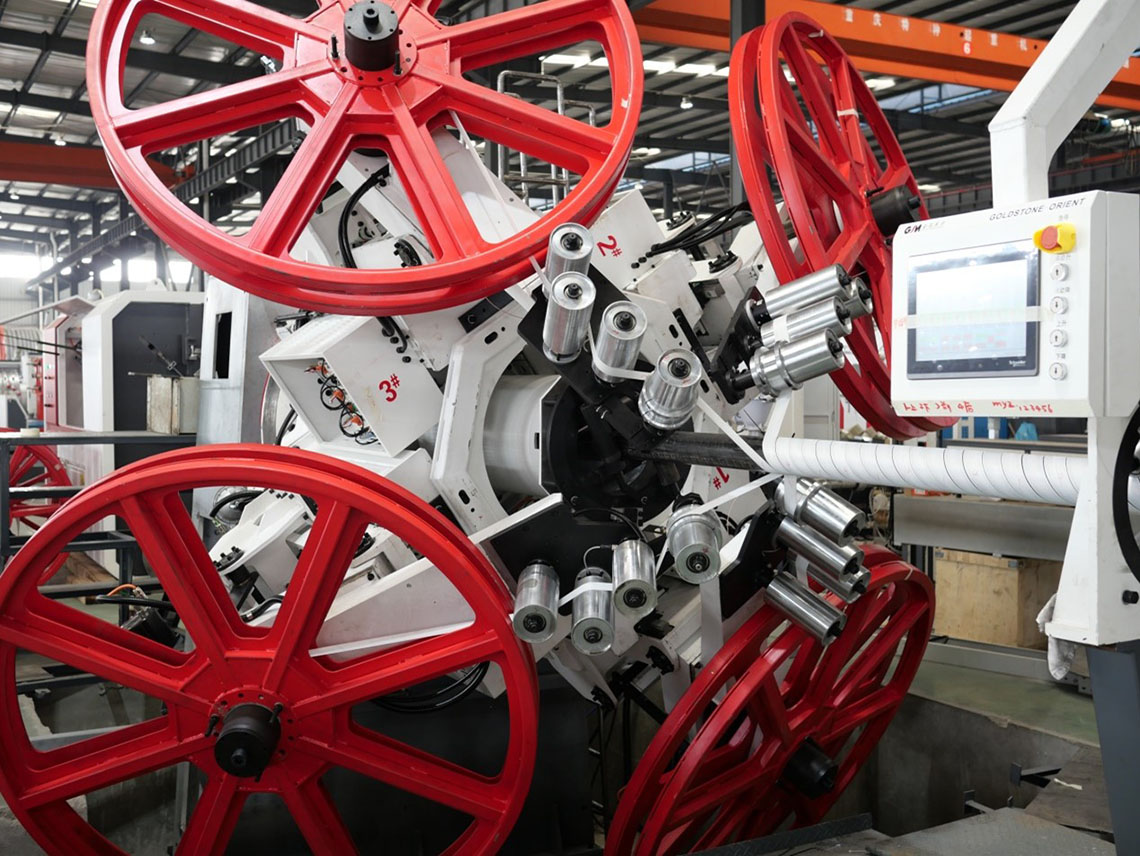

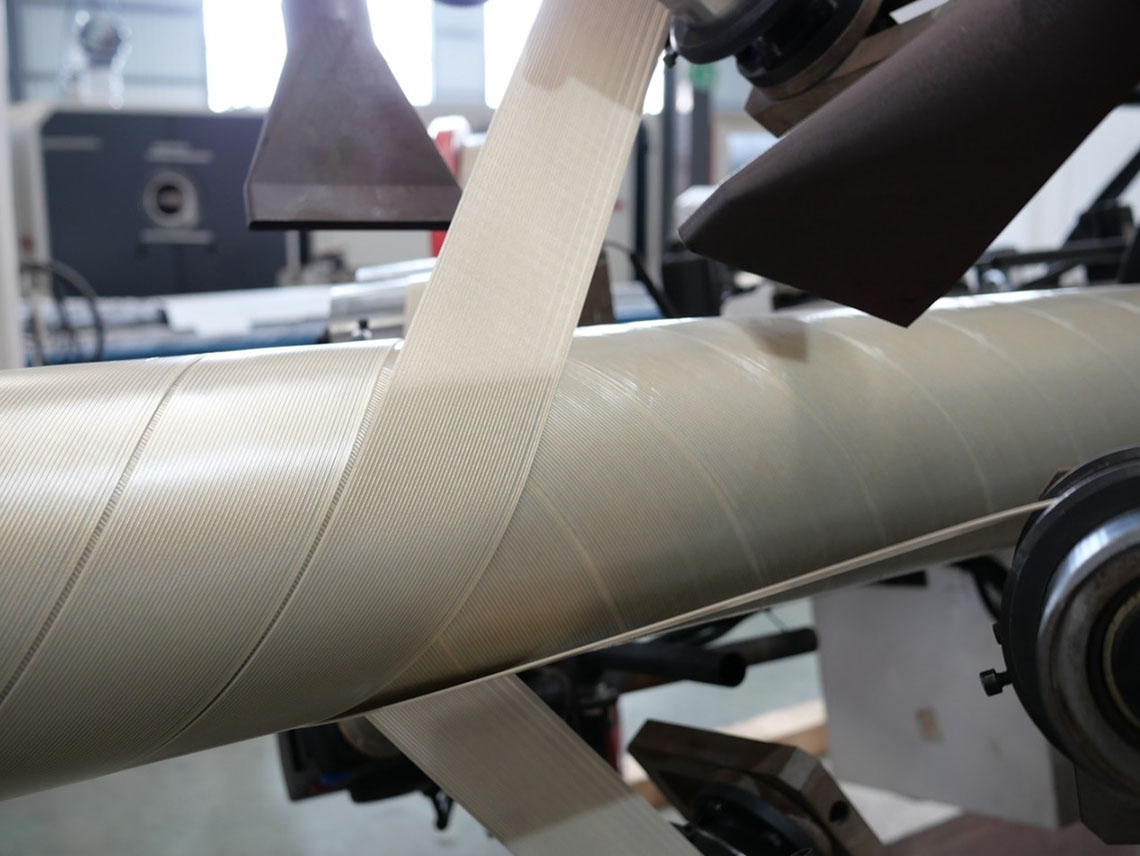

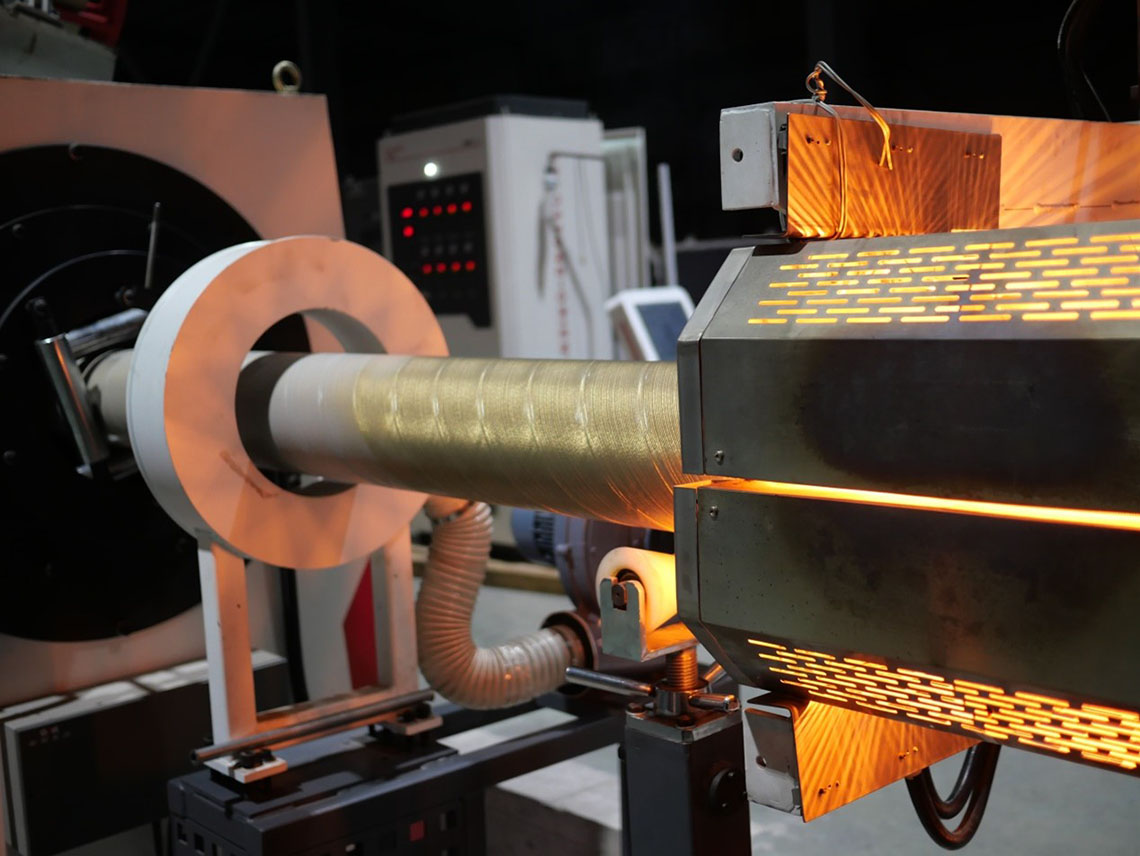

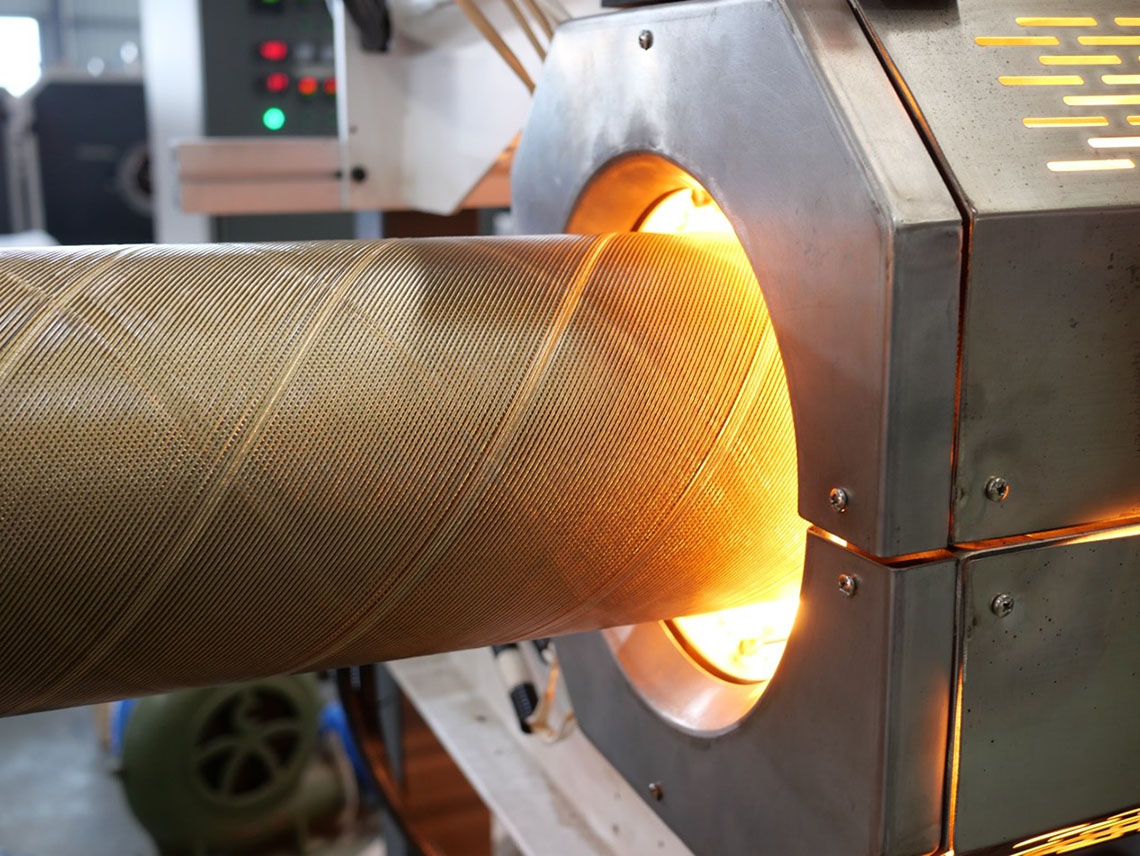

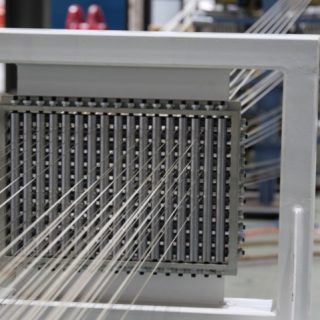

- Reinforcement Layer: Composed of zinc-plated high-strength steel cords arranged in a helical winding pattern (winding angle adjustable between 45°–60° based on pressure requirements). The steel cords are pre-impregnated with thermoplastic adhesive to enhance bonding with the inner/outer layers, eliminating delamination risks under cyclic pressure. For large-diameter pipes (DN200–DN500), a dual-layer steel cord design is adopted to achieve balanced radial and axial load resistance.

- Outer Protective Layer: Extruded from weather-resistant HDPE modified with anti-UV additives and carbon black. This layer resists oxidation, abrasion, and mechanical damage during transportation and installation, extending the pipe’s service life in outdoor or harsh soil environments.

2. Typical Application Scenarios

Leveraging its balance of cost and performance, steel cord-reinforced RTP pipe is well-suited for the following high-demand scenarios:

2.1 Onshore Oil & Gas Transportation

- Shale Gas Gathering Pipelines: The pipe’s flexibility adapts to undulating terrain (e.g., mountainous areas), reducing the need for elbows and joints (joint count reduced by 70% compared to steel pipes, lowering leak risks).

- Oilfield Produced Water Reinjection Pipelines: Resists corrosion from high-salinity (TDS >100,000 mg/L) and high-temperature (up to 80℃) produced water, eliminating the need for internal anti-corrosion coating (a major maintenance cost for steel pipes).

2.2 Mining and Industrial Slurry Transportation

- Coal Mine Slurry Pipelines: The wear-resistant inner liner (HDPE with hardness Shore D 60) withstands abrasion from coal particles (average particle size 0.5–2 mm), extending service life to 8–10 years (vs. 3–5 years for steel pipes).

2.3 Municipal and Infrastructure

- High-Pressure Water Supply Pipelines: For urban water transmission or long-distance water transfer projects, the pipe’s light weight enables manual handling in urban areas (no need for cranes), accelerating installation (laying speed up to 300 m/day, 3x faster than steel pipes).

3. Comparative Advantages Over Traditional Solutions

| Aspect | Steel Cord Reinforced RTP | Traditional Steel Pipe | Aramid Fiber Reinforced RTP |

|---|---|---|---|

| Material Cost | 100% (baseline) | 120% | 250% |

| Installation Cost | 100% | 250% (heavy equipment required) | 120% |

| Annual Maintenance Cost | 100% | 500% (corrosion repair, coating renewal) | 150% (fiber delamination inspection) |

| Total Life-Cycle Cost (20 years) | 100% | 320% | 210% |

| Service Life | >50 years | 20–30 years (with coating) | >50 years |

4. Future Development Trends

To expand its application scope, Goldstone is advancing three key R&D directions for steel cord-reinforced RTP technology:

- High-Corrosion Resistance Upgrade: Developing galvanized steel cords with a thick zinc alloy coating to enhance resistance to acidic media (e.g., H₂S, CO₂) in deep oil & gas wells.

- Large-Diameter Expansion: Optimizing the winding process to develop DN300–DN600 pipes, targeting long-distance onshore oil & gas transmission pipelines (currently dominated by steel pipes).

- Smart Integration: Embedding fiber optic sensors within the steel cord layer to monitor real-time pressure, temperature, and strain. This enables predictive maintenance (e.g., early warning of pressure anomalies) and aligns with the “digital oilfield” trend.

In summary, steel cord-reinforced RTP pipe technology addresses the long-standing trade-off between performance, cost, and scalability in large-diameter composite pipes. It provides a viable, economical alternative to traditional steel pipes and expensive synthetic fiber-reinforced solutions, with broad potential to reshape onshore oil & gas, mining, and municipal infrastructure pipeline markets.