Steel Wire Reinforced Polyethylene (HDPE) Pipe Production Line

HDPE pipe is stronger and more durable, and also reduces material costs.

INTRODUCTION

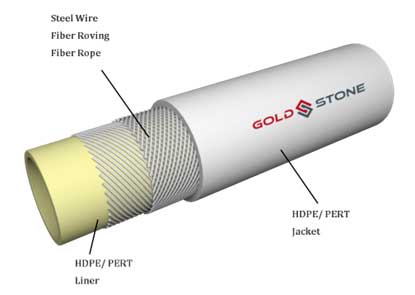

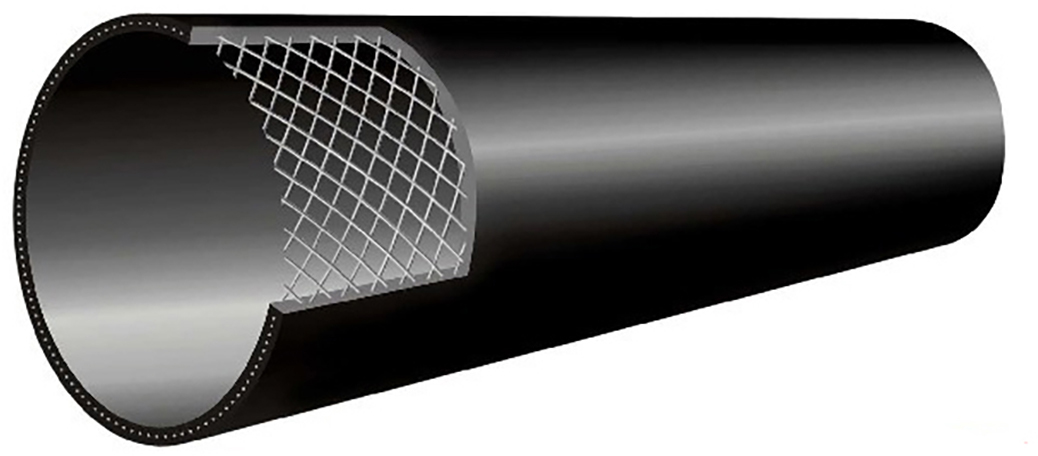

Steel Wire Reinforced Polyethylene (HDPE) Pipe

Reinforced HDPE pipe for water supply is more durable and sabe material cost.

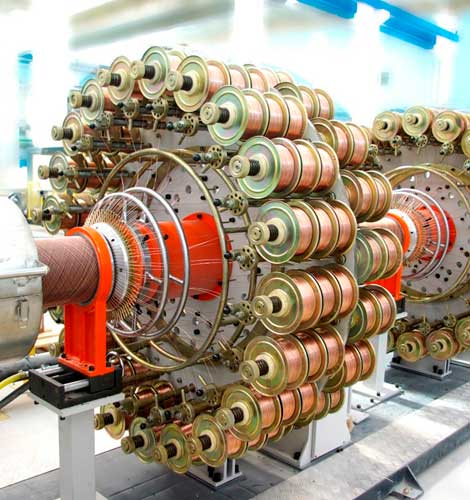

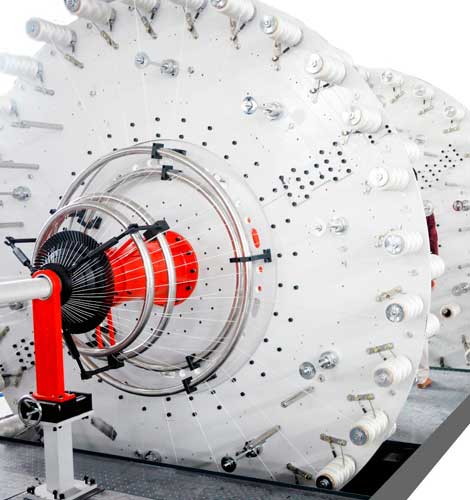

Since 2002, Goldstone’s Steel Wire Reinforced Polyethylene (SRTP) has set the global benchmark for composite pipelines. This innovative product redefined the safety-economy balance in municipal water supply projects, delivering an unrivaled performance-to-price ratio that has transformed both the water supply and broader municipal pipeline sectors.

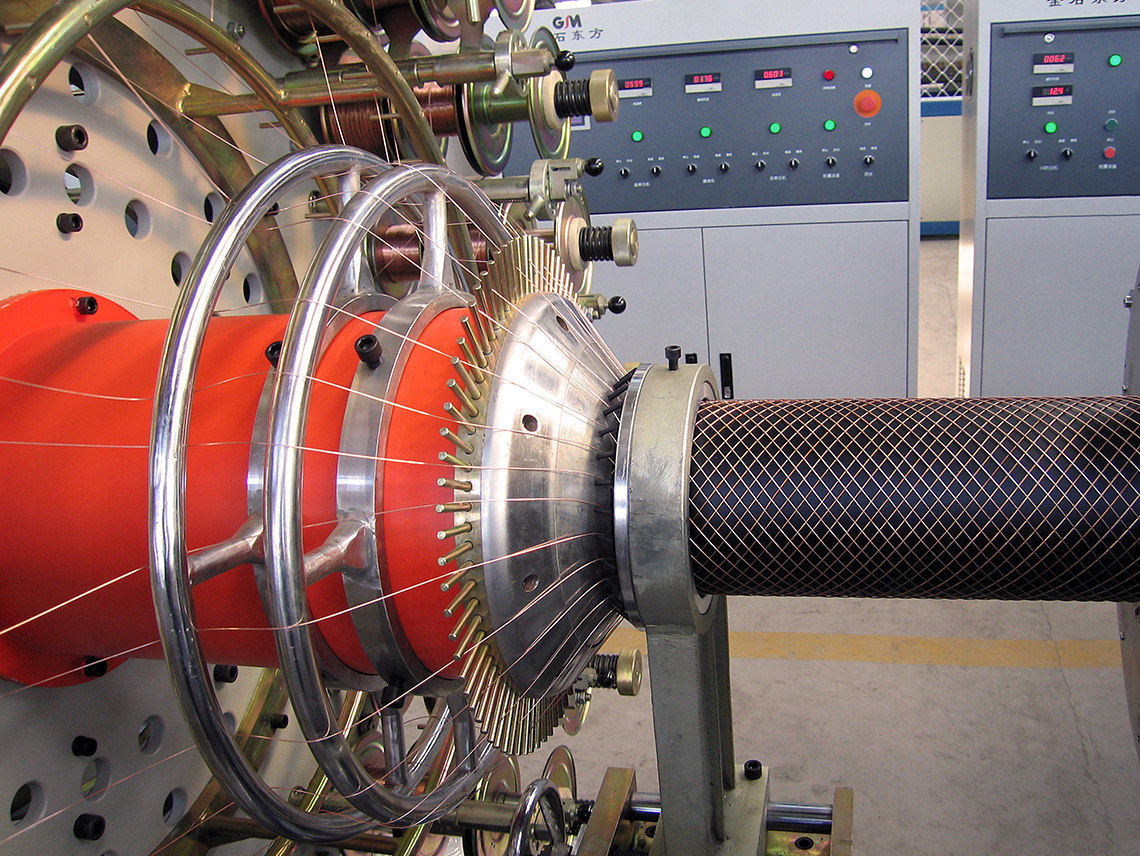

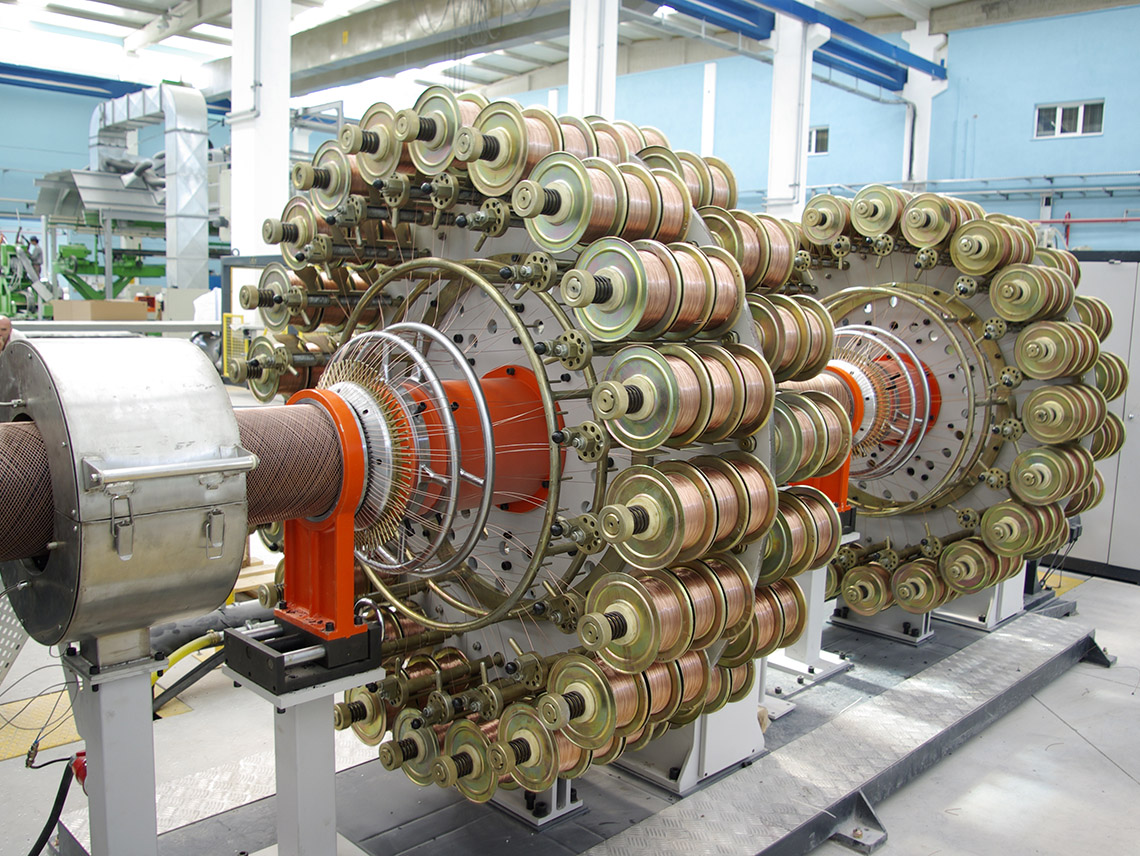

The precision-engineered steel wire wrapping ensures uniform distribution of mechanical stress across the pipe’s entire circumference, a key advancement that allows for significant reduction in the thickness of the HDPE layers without compromising durability. Compared to conventional solid-wall HDPE pipes, this design typically achieves a 20-60% reduction in raw material usage, directly translating to lower production costs.

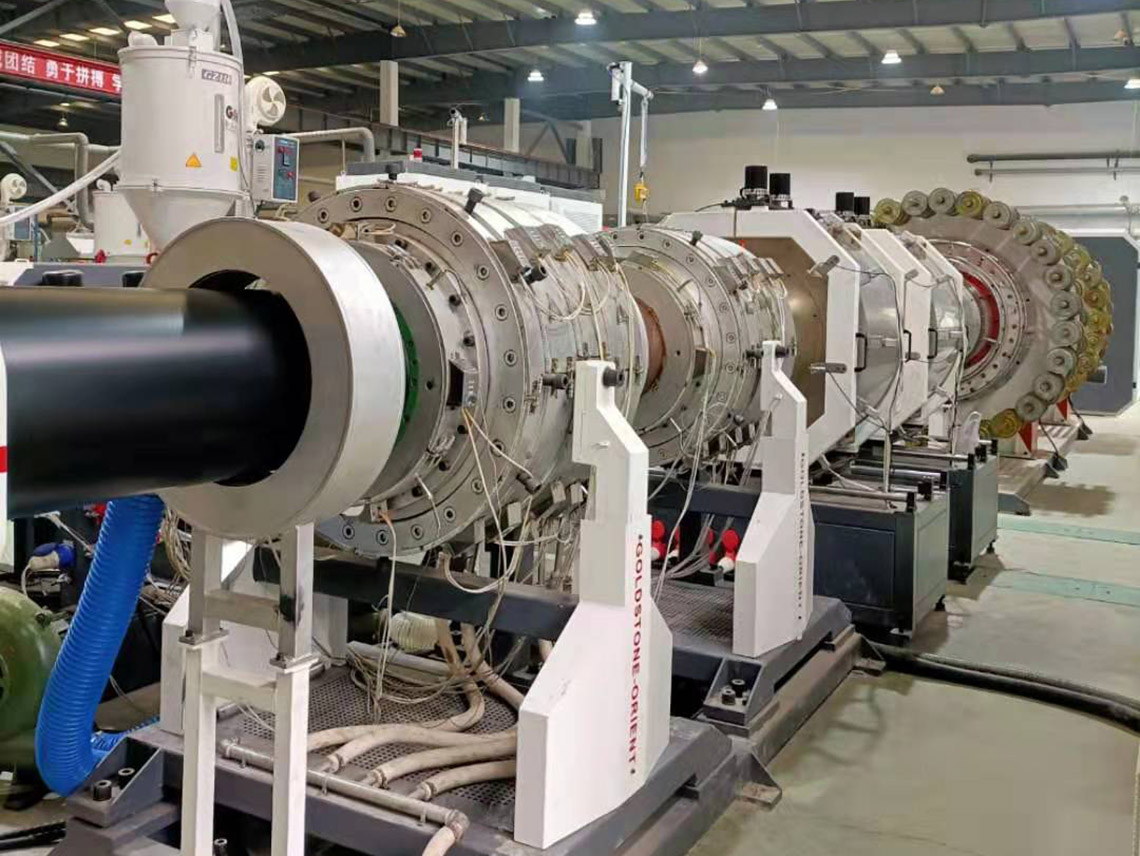

SRTP achieves pressure ratings from PN10 to PN35, while its size range has expanded to larger diameters—up to 1200mm. The larger the pipe, the greater the material cost savings.

Beyond strength and cost savings, the composite structure offers additional advantages: the HDPE outer layer resists corrosion and chemical degradation, while the steel reinforcement prevents radial expansion under high pressure. This combination extends the pipe’s service life to an estimated 25+ years, far exceeding the lifespan of traditional metallic pipes. Installation is also streamlined, as the composite material balances rigidity with flexibility, reducing the need for heavy machinery during laying.

The precision-engineered steel wire wrapping ensures uniform distribution of mechanical stress across the pipe’s entire circumference, a key advancement that allows for significant reduction in the thickness of the HDPE layers without compromising durability. Compared to conventional solid-wall HDPE pipes, this design typically achieves a 20-60% reduction in raw material usage, directly translating to lower production costs.

SRTP achieves pressure ratings from PN10 to PN35, while its size range has expanded to larger diameters—up to 1200mm. The larger the pipe, the greater the material cost savings.

Beyond strength and cost savings, the composite structure offers additional advantages: the HDPE outer layer resists corrosion and chemical degradation, while the steel reinforcement prevents radial expansion under high pressure. This combination extends the pipe’s service life to an estimated 25+ years, far exceeding the lifespan of traditional metallic pipes. Installation is also streamlined, as the composite material balances rigidity with flexibility, reducing the need for heavy machinery during laying.

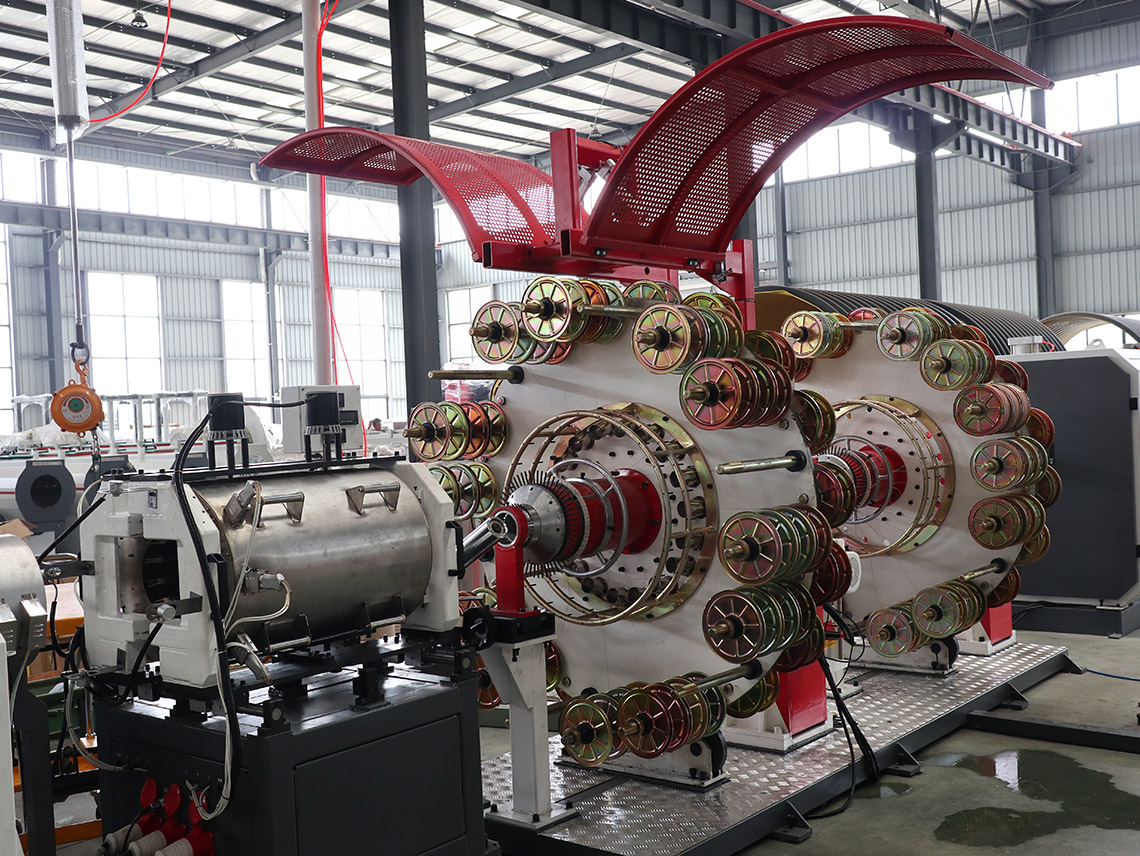

Over the past two decades, more than 2,000 SRTP pipe production machines have been operating across China and several other countries, serving as a solid cornerstone for urban construction. These machines have continuously rolled out high-quality composite pipelines that are widely applied in municipal water supply networks, rainwater and sewage drainage systems.

Even today, SRTP remains one of the best choices for an ideal pipeline, striking an optimal balance between performance and price. Moreover, with the addition of more functional material layers, it continues to evolve and expand into broader applications—such as abrasion-resistant pipelines for mining tailings and slurry.

Even today, SRTP remains one of the best choices for an ideal pipeline, striking an optimal balance between performance and price. Moreover, with the addition of more functional material layers, it continues to evolve and expand into broader applications—such as abrasion-resistant pipelines for mining tailings and slurry.

ADVANTAGES

Steel Reinforced SRTP Pipe vs HDPE Pipe

High Pressure

Reinforced by high-strength steel wire.

The pipe offer higher pressure.

The pipe offer higher pressure.

Saving Cost

Material cost saving up to 30%-40% compared to solid-wall HDPE pipe

Larger Diameter

Pipe diameter range: 50mm-1000mm

Easy Connection

Reliable electro-fusion fitting joint

Comparison

Comparison of Wall Thickness

Comparison