Mining Pipe and Industry

Mining Pipe and Industry

Mining Slurry Transportation Breakthrough

Steel pipes have long been the primary choice for traditional mineral slurry transportation. However, mineral slurry contains large quantities of high-hardness solid particles (e.g., slag, gravel, gangue), and the transportation of this solid-liquid mixture causes constant scouring of the pipeline’s inner wall. This leads to a gradual thinning of the steel pipe wall and even “wear-through leakage” within a short timeframe.

At the same time, mineral slurry often contains acidic, alkaline, and chloride-containing media—all of which trigger two types of corrosion on steel pipes: “chemical corrosion” (e.g., iron dissolution by acidic slurry) and “electrochemical corrosion” (galvanic cell formation at welds and joints). Both forms of corrosion accelerate pipeline perforation. Consequently, steel pipelines typically have a service life of only 5–8 years; in some cases, they even require replacement within 3–5 years, resulting in significant total lifecycle costs.

Thus, “pressure resistance” is not the primary challenge. Instead, the core pain point for mining pipelines lies in addressing abrasion and corrosion—this is key to extending service life and lowering total lifecycle costs.

Abrasion Resistance

Thus, the challenges for mining pipelines extend beyond mere high-pressure resistance—it is even more critical to address wear and corrosion issues. High-Density Polyethylene (HDPE) pipes excel at solving the corrosion problem and offer better abrasion resistance than traditional steel pipes. However, their abrasion resistance still cannot fully meet the practical needs of mining customers.

Ultra-High Molecular Weight Polyethylene (UHMWPE) pipes, by contrast, can provide relatively ideal abrasion resistance. Yet their price is several times that of HDPE pipes, making them economically unfeasible for large-scale promotion and application in mining scenarios.

By contrast, Ultra-High Molecular Weight Polyethylene (UHMWPE) mining pipes boast excellent wear resistance. Their wear rate is only 1/2 to 1/3 that of HDPE pipes and 1/5 to 1/4 that of wear-resistant steel. Even in high-wear extreme operating conditions—such as transporting metal ore coarse slurry or deep-sea mineral slurry—UHMWPE pipes can still maintain a service life of 15 to 25 years.

Nevertheless, the price of UHMWPE materials is 2 to 3 times, or even higher, than that of HDPE. Only in specific scenarios—large-scale mines handling high-value mineral species (e.g., gold ore, copper ore), extreme wear working environments, or long-distance slurry transportation—can the advantages of UHMWPE pipes (long service life and low maintenance) offset their high initial cost. Currently, UHMWPE mining pipes are not economically viable for large-scale promotion in the mining industry.

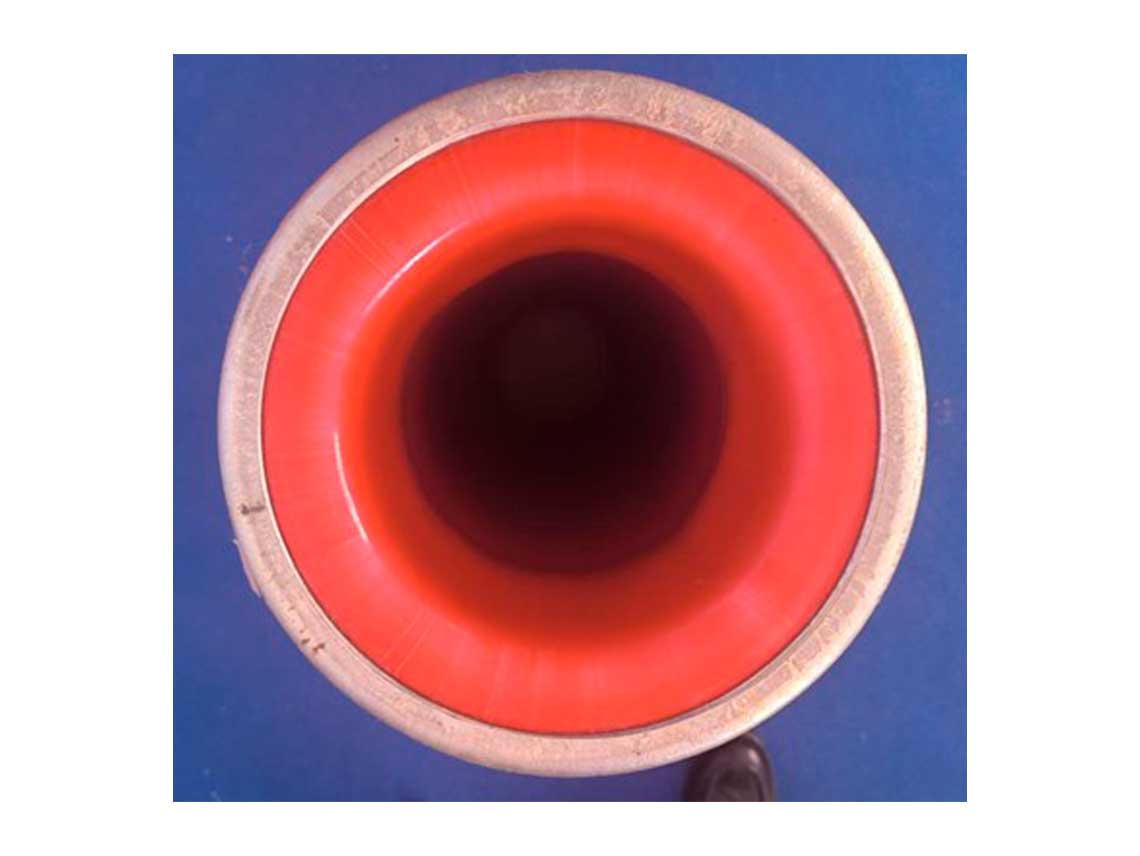

To address this gap in the application field, Goldstone has innovatively developed a high-wear-resistant material lining and integrated it with HDPE-reinforced pipes.

This new pipe type not only meets the demands for wear resistance and corrosion resistance but also substantially enhances the pipe’s pressure resistance (3.0–8.0 MPa). At the same time, it offers favorable economic viability, making it an ideal pipeline for mineral slurry transportation.

Corrosion Proof

As a type of conventional polyethylene plastic pipe, High-Density Polyethylene (HDPE) mining pipes exhibit excellent corrosion resistance. They barely react with acidic, alkaline, or saline components in mineral slurry, thus completely resolving the corrosion issues that trouble steel pipes. In terms of abrasion resistance, HDPE mining pipes outperform conventional steel pipes by a large margin—their wear rate is merely 1/3 to 1/6 that of steel pipes. With a smooth, scale-free inner wall, these pipes minimize transportation resistance and improve energy efficiency effectively. In medium-to-low wear scenarios (e.g., coal washing, non-metallic mineral processing), HDPE mining pipes have a service life of 8 to 12 years. They also feature a moderate initial cost, delivering outstanding cost-effectiveness. However, their service life remains relatively short when used for transporting high-hardness mineral slurry. Yet another limitation is that HDPE material still fails to address the problem of scaling within a short service period.

In the abrasion resistance test, Goldstone’s polymer liner delivers significantly better performance than traditional steel pipes. Notably, it even outperforms UHMWPE in certain aspects—further validating its competitiveness in addressing the core wear challenge of mining pipelines.

At the same time, we also provide a variety of supporting high-pressure wear-resistant connecting fittings, ensuring that the fittings do not become weak points of the entire pipeline system and achieve a service life equivalent to that of the pipes.

At the same time, in line with the overall solution for mineral slurry transportation pipelines, we also provide a variety of supporting high-pressure wear-resistant connecting fittings. These fittings are designed to match the core performance of the main pipeline (such as high-pressure resistance and wear resistance), which ensures they do not become weak points in the entire pipeline system. Ultimately, the fittings achieve a service life equivalent to that of the main pipes, further guaranteeing the long-term stable operation of the mineral slurry transportation system.

A Flexible pipe with Abrasion Resistance Liner

Recent field tests confirm its exceptional suitability for field mining slurry transportation (tailings, mineral concentrate, or coal slurry):

Rapid Terrain-Adaptive Deployment: As a continuous spooled pipe, it eliminates on-site jointing (a major bottleneck for mining projects) and bends easily over rough mining terrain (hills, gravel, or temporary access roads). Installation via plowing or surface laying reduces on-site construction time by over 50% compared to segmented concrete/steel mining slurry pipes.

Extended Wear & Corrosion Resistance: The steel tape layer resists particle scouring (the leading cause of mining pipe failure), while the thermoplastic inner layer withstands acidic/alkaline mining wastewater. This extends service life to 15–20 years — 2–3x longer than conventional mining slurry pipes, slashing replacement frequency and downtime.